The Essential Guide to Cassette Type Single Facer Machines in Packaging Industry

May 06,2025

In the packaging machinery sector, cassete type single facer machines play a critical role in the production of corrugated cardboard. These machines are specifically designed to convert flat paper sheets into a structured form of packaging that is both lightweight and durable. The single facer machine operates by adhering a corrugated medium between two liners, resulting in a strong and versatile

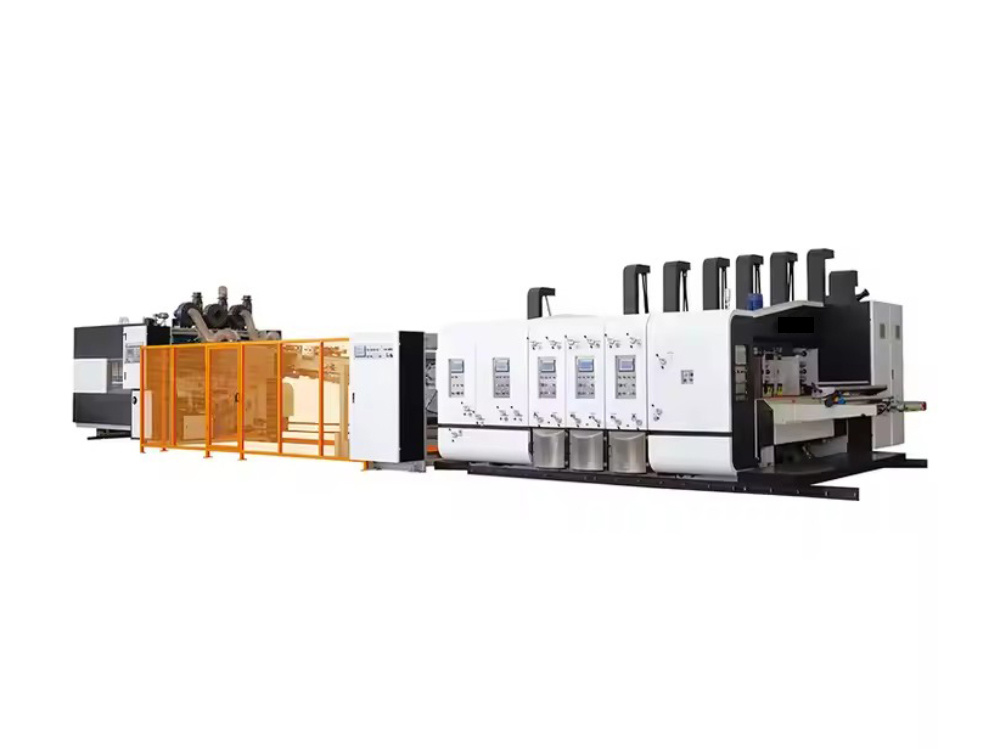

In the packaging machinery sector, cassete type single facer machines play a critical role in the production of corrugated cardboard. These machines are specifically designed to convert flat paper sheets into a structured form of packaging that is both lightweight and durable. The single facer machine operates by adhering a corrugated medium between two liners, resulting in a strong and versatile packaging material that is widely used in various industries.

One of the primary advantages of the cassette type single facer machine is its modular design. This feature allows for easy maintenance and adjustment, making it an ideal choice for manufacturers seeking efficiency without sacrificing productivity. The cassette system enables quick changeovers between different sizes and types of corrugated materials, which can significantly reduce downtime during production.

The operational efficiency of a cassete type single facer machine stems from its ability to consistently produce high-quality corrugated sheets. With advanced control systems, these machines can automatically adjust parameters such as the temperature and pressure applied during the gluing process, ensuring optimal bonding strength for the paper layers. This precision not only enhances the quality of the final product but also improves overall production rates, allowing businesses to meet rising demand without compromising on quality.

In addition to efficiency and quality, the versatility of cassette type single facer machines allows them to cater to a wide range of applications. They are used in the manufacturing of boxes, displays, and other packaging solutions for industries such as food and beverage, electronics, and consumer goods. This adaptability makes them a valuable asset in any packaging operation, facilitating the production of tailored solutions to meet specific customer requirements.

Furthermore, the integration of technology in these machines has enabled manufacturers to better monitor and control their processes. With the advent of Industry 4.0, many cassette type single facer machines are now equipped with IoT capabilities. This allows for real-time data collection and analysis, enabling manufacturers to optimize their production processes, reduce waste, and improve overall efficiency.

In conclusion, cassete type single facer machines represent a significant advancement in the packaging machinery sector. Their modular design, operational efficiency, and versatility make them indispensable for manufacturers looking to enhance their production capabilities. As the demand for sustainable packaging solutions continues to grow, investing in advanced machinery like the cassette type single facer can provide businesses with a competitive edge in the evolving market.

One of the primary advantages of the cassette type single facer machine is its modular design. This feature allows for easy maintenance and adjustment, making it an ideal choice for manufacturers seeking efficiency without sacrificing productivity. The cassette system enables quick changeovers between different sizes and types of corrugated materials, which can significantly reduce downtime during production.

The operational efficiency of a cassete type single facer machine stems from its ability to consistently produce high-quality corrugated sheets. With advanced control systems, these machines can automatically adjust parameters such as the temperature and pressure applied during the gluing process, ensuring optimal bonding strength for the paper layers. This precision not only enhances the quality of the final product but also improves overall production rates, allowing businesses to meet rising demand without compromising on quality.

In addition to efficiency and quality, the versatility of cassette type single facer machines allows them to cater to a wide range of applications. They are used in the manufacturing of boxes, displays, and other packaging solutions for industries such as food and beverage, electronics, and consumer goods. This adaptability makes them a valuable asset in any packaging operation, facilitating the production of tailored solutions to meet specific customer requirements.

Furthermore, the integration of technology in these machines has enabled manufacturers to better monitor and control their processes. With the advent of Industry 4.0, many cassette type single facer machines are now equipped with IoT capabilities. This allows for real-time data collection and analysis, enabling manufacturers to optimize their production processes, reduce waste, and improve overall efficiency.

In conclusion, cassete type single facer machines represent a significant advancement in the packaging machinery sector. Their modular design, operational efficiency, and versatility make them indispensable for manufacturers looking to enhance their production capabilities. As the demand for sustainable packaging solutions continues to grow, investing in advanced machinery like the cassette type single facer can provide businesses with a competitive edge in the evolving market.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China