Unlocking Efficiency: The Benefits of Semi-Automatic Flute Laminators

May 27,2025

Unlocking Efficiency: The Benefits of Semi-Automatic Flute Laminators

Table of Contents

Introduction to Semi-Automatic Flute Laminators

What Are Flute Laminators?

Understanding Semi-Automatic Systems

Advantages of Semi-Automatic Flute Laminators

Cost Efficiency

Improved Production Speed

Consistent Product Quality

Flexibility

Unlocking Efficiency: The Benefits of Semi-Automatic Flute Laminators

Table of Contents

- Introduction to Semi-Automatic Flute Laminators

- What Are Flute Laminators?

- Understanding Semi-Automatic Systems

- Advantages of Semi-Automatic Flute Laminators

- Applications in the Packaging Industry

- Choosing the Right Flute Laminator for Your Needs

- Maintenance and Care of Semi-Automatic Flute Laminators

- Frequently Asked Questions

- Conclusion

Introduction to Semi-Automatic Flute Laminators

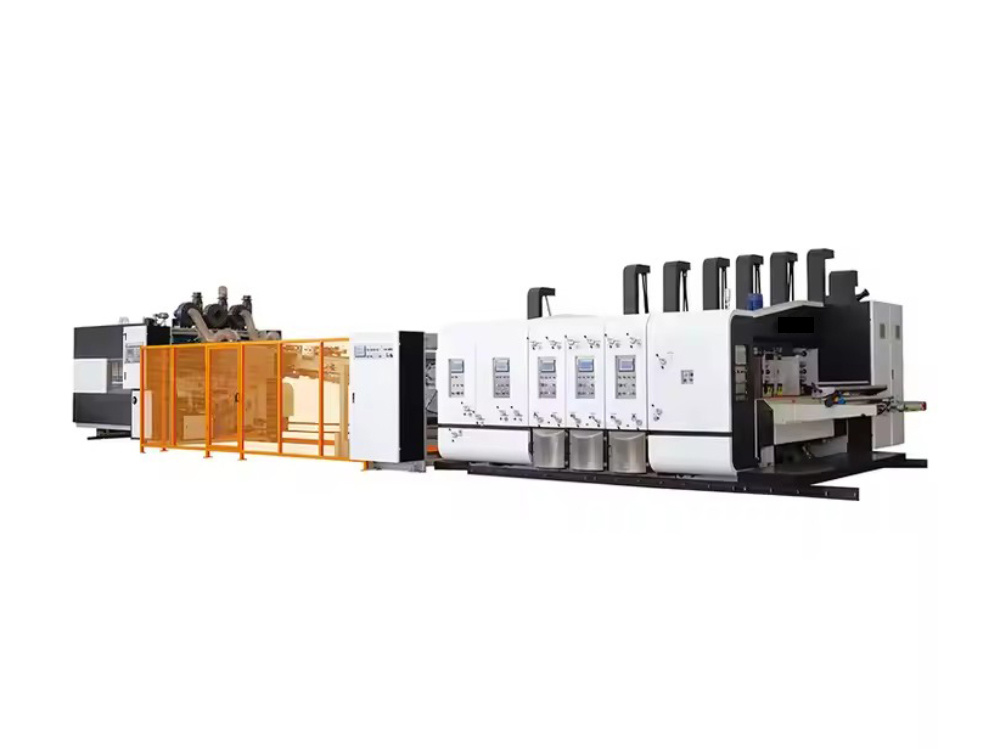

In today’s competitive packaging landscape, businesses are continually seeking ways to enhance operational efficiency and product quality. **Semi-automatic flute laminators** have emerged as a critical solution for manufacturers, offering a balance between automation and manual control. This article delves into the features and benefits of these machines, aiding businesses in making informed decisions that can propel their productivity and profitability.

What Are Flute Laminators?

Flute laminators are specialized machines designed to apply a layer of protective material, often paper or plastic, to various substrates. These machines utilize a process known as lamination, which enhances the durability and aesthetic appeal of packaging products. The **semi-automatic variant** allows for some manual intervention while still leveraging automated functions, making it ideal for small to medium-sized production lines.

Understanding Semi-Automatic Systems

Semi-automatic flute laminators combine the operational efficiency of fully automated systems with the flexibility of manual control. Operators can adjust settings and monitor the process closely, ensuring optimal results without sacrificing speed. This hybrid approach caters to businesses that require versatility in their production lines while still needing to maintain a high level of efficiency.

Advantages of Semi-Automatic Flute Laminators

Cost Efficiency

Investing in semi-automatic flute laminators can significantly reduce production costs. By minimizing labor requirements and maximizing output, these machines enable businesses to allocate resources more effectively. The initial investment is often balanced out by long-term savings, making them an attractive option for companies looking to enhance their bottom line.

Improved Production Speed

One of the key benefits of semi-automatic flute laminators is their ability to maintain high production speeds without compromising quality. With automated feeding and alignment systems, these machines can rapidly process materials, ensuring that your production line remains efficient and responsive to demand fluctuations.

Consistent Product Quality

Quality control is paramount in the packaging industry. Semi-automatic flute laminators are designed to deliver consistent results, minimizing variation in product output. The technology employed in these machines ensures that every laminated product meets the required specifications, thereby enhancing customer satisfaction and reducing waste.

Flexibility and Versatility

In an industry where customization is key, the **flexibility** of semi-automatic flute laminators cannot be overstated. These machines can handle a variety of substrates and lamination materials, allowing businesses to diversify their product offerings without investing in multiple machines. Furthermore, operators can easily switch between different production runs, adapting to changing market demands.

Applications in the Packaging Industry

Semi-automatic flute laminators find applications in various sectors within the packaging industry. From food and beverage packaging to consumer goods, the versatility of these machines allows manufacturers to create a wide array of products. Common applications include:

- **Packaging for Food Products**: Ensuring that products remain fresh while providing an attractive presentation.

- **Consumer Electronics**: Laminated packaging that protects sensitive items while showcasing them effectively.

- **Cosmetics and Personal Care**: High-quality packaging that exudes luxury and quality.

Choosing the Right Flute Laminator for Your Needs

Selecting the ideal semi-automatic flute laminator requires careful consideration of various factors. Businesses should evaluate their production volume, substrate types, and specific product requirements. Additionally, it’s essential to consider the machine's features, such as:

- **Speed and Efficiency**: Look for laminators that can handle your expected output.

- **Ease of Use**: User-friendly controls can minimize training time and enhance productivity.

- **Maintenance Requirements**: Opt for machines that are easy to maintain to reduce downtime.

Maintenance and Care of Semi-Automatic Flute Laminators

Proper maintenance is vital to ensuring the longevity and efficiency of semi-automatic flute laminators. Regular cleaning, lubrication, and inspection of moving parts are essential to prevent breakdowns and maintain optimal performance. It’s advisable to develop a maintenance schedule and train staff on proper care procedures, ensuring that the machine operates smoothly over its lifespan.

Frequently Asked Questions

1. What is a semi-automatic flute laminator?

A semi-automatic flute laminator is a machine that applies a layer of protective material to substrates, combining manual adjustments with automated processes for efficiency.

2. How does a semi-automatic flute laminator improve production efficiency?

These machines enhance production efficiency by reducing labor costs, increasing output speeds, and ensuring consistent product quality.

3. What industries benefit the most from using semi-automatic flute laminators?

Industries such as food and beverage packaging, consumer electronics, and cosmetics benefit greatly from the versatility and efficiency of semi-automatic flute laminators.

4. How can I choose the right flute laminator for my business?

Evaluate your production needs, substrate types, required output speeds, and maintenance considerations when selecting a flute laminator.

5. What maintenance is required for semi-automatic flute laminators?

Regular cleaning, lubrication, and inspection of machine components are essential to maintaining optimal performance and prolonging the machine’s lifespan.

Conclusion

The integration of **semi-automatic flute laminators** into manufacturing processes represents a significant step towards achieving operational excellence. By unlocking efficiency and enhancing product quality, these machines empower businesses to meet the demands of the modern packaging industry. As companies continue to seek innovative solutions to streamline operations, investing in semi-automatic flute laminators stands out as a smart strategy to remain competitive and successful in a rapidly evolving market.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China