Why the ZL-1450 Laminator is Essential for High-Quality Packaging

Jun 04,2025

Why the ZL-1450 Laminator is Essential for High-Quality Packaging

Table of Contents

Introduction to the ZL-1450 Laminator

The Importance of Lamination in Packaging

Key Features of the ZL-1450 Laminator

Applications of the ZL-1450 Laminator in Various Industries

Benefits of Using the ZL-1450 Laminator for Your Business

Comparative Advantage of the ZL-1450 Laminator Over Oth

Why the ZL-1450 Laminator is Essential for High-Quality Packaging

Table of Contents

- Introduction to the ZL-1450 Laminator

- The Importance of Lamination in Packaging

- Key Features of the ZL-1450 Laminator

- Applications of the ZL-1450 Laminator in Various Industries

- Benefits of Using the ZL-1450 Laminator for Your Business

- Comparative Advantage of the ZL-1450 Laminator Over Other Laminators

- Maintenance and Care for Longevity

- Conclusion

- Frequently Asked Questions

Introduction to the ZL-1450 Laminator

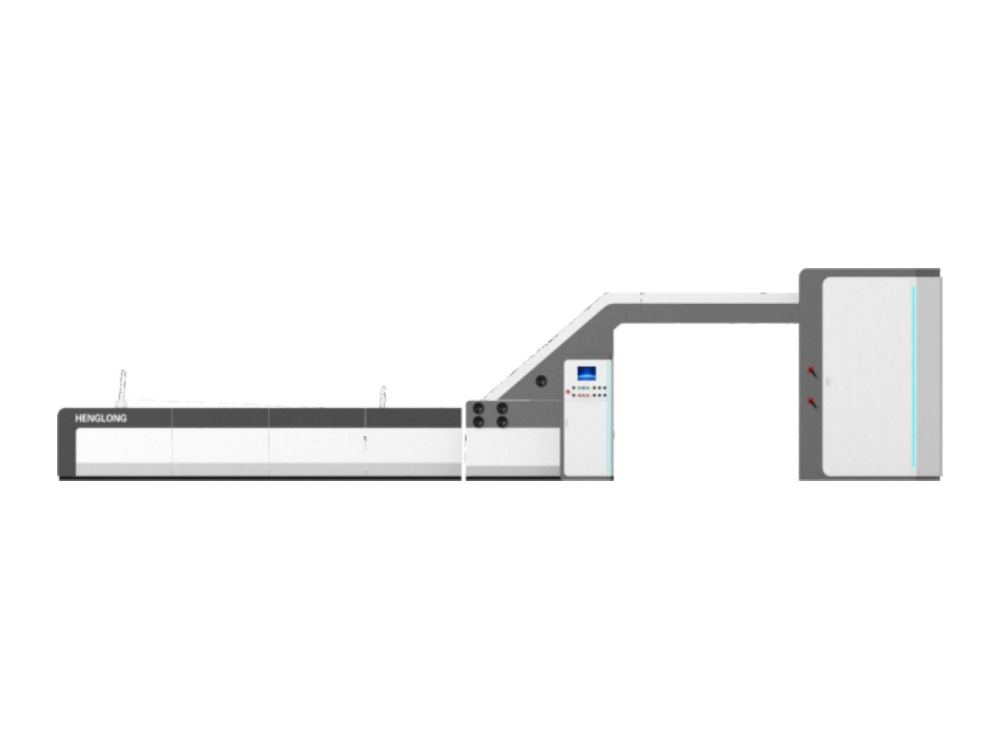

The **ZL-1450 Laminator** stands as a premier choice in the realm of packaging machinery, particularly for businesses seeking to enhance their packaging quality. This machine is engineered to deliver top-notch lamination, which plays a crucial role in the durability and attractiveness of packaging materials.

In today's competitive market, where the visual appeal of packaging can make or break a product's success, investing in a high-quality laminator like the ZL-1450 is essential. This article delves into the numerous benefits, features, and applications of the ZL-1450 Laminator, illustrating why it is indispensable for businesses aiming for excellence in packaging.

The Importance of Lamination in Packaging

Lamination is a process that involves applying a thin layer of plastic film over printed materials, providing a protective barrier against environmental factors such as moisture, UV rays, and physical wear. The significance of lamination in packaging cannot be overstated, as it not only enhances the aesthetic appeal but also extends the lifespan of products.

Enhancing Aesthetic Appeal

A well-laminated package boasts a glossy or matte finish that elevates its visual attractiveness, thereby catching the consumer's eye. This is especially important in retail environments, where the packaging often plays a pivotal role in influencing purchasing decisions.

Protecting Your Product

Lamination serves as a protective shield, ensuring that packaging withstands the rigors of transportation and storage. This is particularly crucial for products that are sensitive to moisture or require a pristine appearance upon reaching the consumer.

Key Features of the ZL-1450 Laminator

The **ZL-1450 Laminator** is equipped with a host of features that set it apart from other laminators in the market. Understanding these features is essential for businesses considering this investment.

Advanced Technology

The ZL-1450 employs cutting-edge technology that ensures uniform application of lamination, which is vital for achieving consistent results across multiple batches.

User-Friendly Interface

Designed with the operator in mind, the ZL-1450 features an intuitive interface that simplifies operation. This minimizes the learning curve and increases efficiency in the workplace.

Versatility in Laminating Materials

This laminator can accommodate various types of materials, from paper to plastic, making it an ideal choice for diverse packaging needs. Whether you are working with labels, brochures, or product packaging, the ZL-1450 can handle it all.

High-Speed Operation

The ZL-1450 is engineered for high-speed lamination, enabling businesses to meet tight deadlines without compromising on quality. This efficiency translates to increased productivity and lower operational costs.

Applications of the ZL-1450 Laminator in Various Industries

The versatility of the ZL-1450 makes it suitable for a range of industries, each benefiting from its advanced features and capabilities.

Pharmaceutical Industry

In the pharmaceutical sector, packaging requires a high level of protection and compliance with regulations. The ZL-1450 ensures that packaging materials are well-protected, maintaining the integrity of the products inside.

Food and Beverage Industry

For food packaging, ensuring freshness and safety is paramount. The ZL-1450 provides an effective barrier against contaminants, extending shelf life while enhancing the overall presentation of food products.

Cosmetics and Personal Care

In the cosmetics industry, packaging design is crucial for brand appeal. The glossy finish achieved through lamination adds a premium feel to cosmetic products, enticing consumers.

Electronics Packaging

Electronics are often sensitive to environmental factors, making protective packaging essential. The ZL-1450 laminator helps safeguard delicate items during transportation and display, ensuring they reach consumers intact.

Benefits of Using the ZL-1450 Laminator for Your Business

Investing in the ZL-1450 Laminator brings numerous advantages that can significantly impact your business operations and bottom line.

Cost-Effectiveness

By enhancing the durability of packaging, the ZL-1450 helps reduce waste associated with damaged products. This cost-effectiveness extends to decreased material costs, as well as savings related to product returns.

Improved Brand Image

High-quality packaging reflects positively on your brand. Using the ZL-1450 ensures that your products are presented professionally, helping to build customer trust and loyalty.

Increased Productivity

With its high-speed operation and user-friendly design, the ZL-1450 allows for rapid production cycles. This efficiency enables businesses to take on larger orders and fulfill them in a timely manner.

Comparative Advantage of the ZL-1450 Laminator Over Other Laminators

While there are many laminators available on the market, the ZL-1450 stands out due to its unique combination of features, versatility, and performance.

Superior Quality Control

The ZL-1450's advanced technology ensures that every product is laminated to perfection, reducing the incidence of defects compared to other models.

Enhanced Durability

Unlike some other laminators, the ZL-1450 is built with robust components that withstand heavy usage, providing a longer lifespan and a better return on investment.

Greater Flexibility

The ability to laminate various materials and sizes makes the ZL-1450 more versatile than its competitors, catering to a wider range of packaging needs.

Maintenance and Care for Longevity

To ensure that the ZL-1450 Laminator continues to operate efficiently, regular maintenance is essential.

Cleaning

Regularly clean the laminator’s rollers and surface to prevent buildup that could affect performance. This simple step can significantly enhance the machine's longevity.

Periodic Inspections

Conduct periodic inspections to check for any wear and tear. Addressing minor issues promptly can prevent larger problems down the line.

Professional Servicing

Consider professional servicing at least once a year to ensure that all components are functioning optimally and to extend the life of your laminator.

Conclusion

In an increasingly competitive marketplace, high-quality packaging is more critical than ever. The **ZL-1450 Laminator** emerges as an essential asset for businesses aiming to enhance their packaging solutions. With its advanced technology, versatility, and numerous benefits, this laminator not only improves the aesthetic appeal of products but also enhances their durability, ensuring they reach consumers in pristine condition. Investing in the ZL-1450 Laminator is a strategic move towards achieving excellence in packaging that can lead to increased customer satisfaction and loyalty.

Frequently Asked Questions

1. What types of materials can the ZL-1450 Laminator handle?

The ZL-1450 Laminator can handle a variety of materials, including paper, plastic, and film, making it versatile for different packaging needs.

2. How does lamination enhance product durability?

Lamination creates a protective barrier that shields products from moisture, UV rays, and physical damage, thereby extending their shelf life.

3. Is the ZL-1450 easy to operate?

Yes, the ZL-1450 features a user-friendly interface that simplifies operation, allowing operators to quickly become proficient.

4. What maintenance is required for the ZL-1450 Laminator?

Regular cleaning, periodic inspections for wear and tear, and professional servicing are recommended to maintain optimal performance.

5. Can the ZL-1450 help reduce packaging waste?

Yes, by enhancing the durability of packaging, the ZL-1450 helps minimize product damage and returns, ultimately reducing waste.

TAG:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China