Exploring the Benefits of Cassette Type Single Facer Machines in Packaging

Jun 20,2025

Exploring the Benefits of Cassette Type Single Facer Machines in Packaging

Table of Contents

Introduction to Cassette Type Single Facer Machines

What is a Cassette Type Single Facer Machine?

Key Benefits of Cassette Type Single Facer Machines

1. Efficiency and Speed

2. Versatility in Packaging

3. Cost-Effectiveness

4. Quality Ou

Exploring the Benefits of Cassette Type Single Facer Machines in Packaging

Table of Contents

- Introduction to Cassette Type Single Facer Machines

- What is a Cassette Type Single Facer Machine?

- Key Benefits of Cassette Type Single Facer Machines

- 1. Efficiency and Speed

- 2. Versatility in Packaging

- 3. Cost-Effectiveness

- 4. Quality Output

- 5. Ease of Maintenance

- Applications of Cassette Type Single Facer Machines in Various Industries

- Comparison with Other Packaging Machines

- Future Trends in Packaging Technology

- Conclusion

- FAQs

Introduction to Cassette Type Single Facer Machines

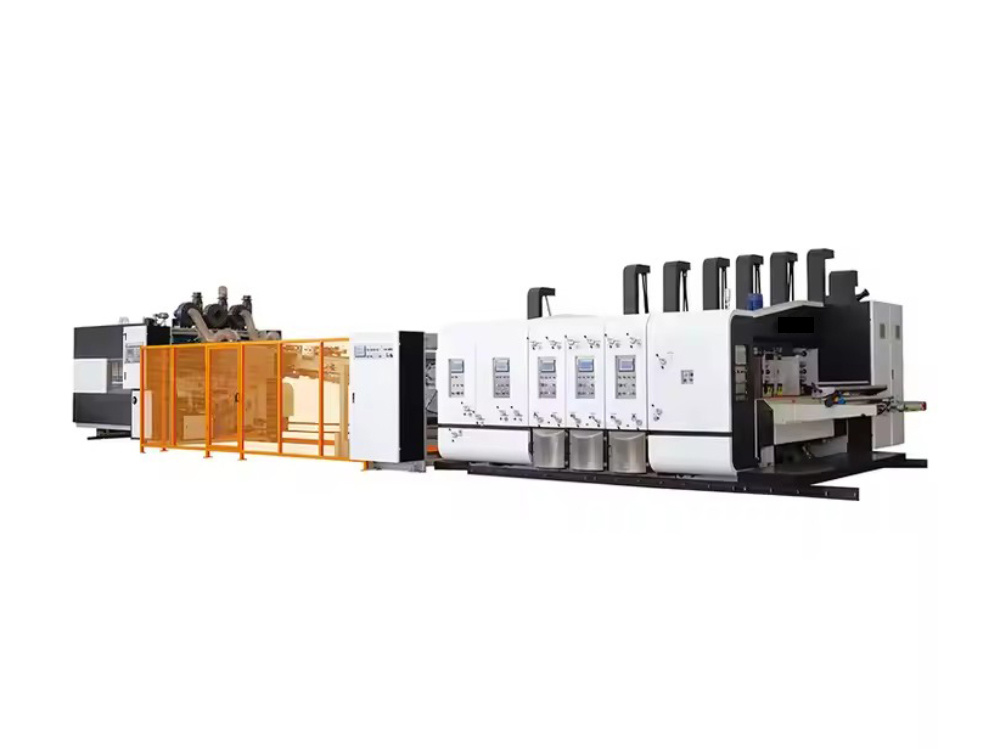

In the fast-evolving world of packaging machinery, **cassette type single facer machines** stand out due to their remarkable features and capabilities. As industries increasingly seek efficient and cost-effective solutions, these machines are becoming essential in the production of corrugated cardboard. Their unique design allows for fast changeovers and customization, making them a preferred choice in the packaging sector.

What is a Cassette Type Single Facer Machine?

A **cassette type single facer machine** is a critical piece of equipment used in the manufacturing of corrugated sheets. It combines the flute-forming and adhesive application processes into one continuous workflow. Its cassette design enables quick adjustments for different sizes and flute configurations, enhancing flexibility and productivity on the production line.

Key Benefits of Cassette Type Single Facer Machines

1. Efficiency and Speed

One of the standout benefits of **cassette type single facer machines** is their efficiency. These machines can produce high volumes of corrugated sheets in a short period. The streamlined process minimizes downtime and maximizes output, allowing manufacturers to meet increasing demand without sacrificing quality. Fast setup times further enhance their efficiency, enabling quick transitions between different product specifications.

2. Versatility in Packaging

The versatility of **cassette type single facer machines** allows them to cater to a wide range of packaging needs. They can accommodate various sizes and types of flutes, making them suitable for different applications, from small cartons to large shipping boxes. This adaptability is crucial for businesses that require flexibility to meet diverse customer demands.

3. Cost-Effectiveness

Investing in **cassette type single facer machines** can yield significant cost savings. Their efficient production capabilities reduce labor costs and energy consumption, resulting in lower operational expenses. Additionally, the durability and reliability of these machines mean reduced maintenance costs over time. Companies can maximize their return on investment while maintaining high production standards.

4. Quality Output

Quality is paramount in packaging, and **cassette type single facer machines** excel in this area. They produce consistently high-quality corrugated sheets with precise flute formations and adhesive applications. This ensures that the final product is robust and reliable, meeting industry standards and customer expectations. High-quality output enhances brand reputation and customer satisfaction.

5. Ease of Maintenance

Maintenance is often a concern for manufacturers, but **cassette type single facer machines** are designed with ease of service in mind. Their modular components simplify repairs and replacements, minimizing downtime. Regular maintenance checks are straightforward, allowing operators to keep machines running smoothly without extensive training or specialized knowledge.

Applications of Cassette Type Single Facer Machines in Various Industries

The applications of **cassette type single facer machines** extend across various industries. In the food sector, they play a vital role in creating packaging that ensures product safety and extends shelf life. In the electronics industry, they provide protective packaging for fragile components. The automotive sector also benefits from these machines, as they produce strong packaging solutions for parts and accessories. Their versatility makes them a suitable choice for any industry requiring reliable and efficient packaging solutions.

Comparison with Other Packaging Machines

When comparing **cassette type single facer machines** with other types of packaging machinery, several advantages emerge. Unlike traditional single facer machines, which may have longer setup times and limited functionality, cassette type machines offer rapid changeovers and enhanced flexibility. Additionally, they outperform many rotary or inline machines regarding speed and output quality, making them a superior choice for manufacturers looking to optimize their packaging processes.

Future Trends in Packaging Technology

The future of packaging technology is promising, with innovations focusing on sustainability and efficiency. Manufacturers are increasingly turning to eco-friendly materials and practices, and **cassette type single facer machines** are adapting to these trends with features that support sustainable production. Continuous advancements, such as automation and integration with smart technology, are expected to enhance the capabilities of these machines further, ensuring they remain a vital part of the packaging landscape.

Conclusion

**Cassette type single facer machines** represent a significant advancement in the packaging industry. Their efficiency, versatility, cost-effectiveness, and high-quality output make them an invaluable asset for manufacturers. As industries continue to evolve, these machines are poised to meet growing demands while maintaining productivity and quality standards. Investing in a cassette type single facer machine may very well be the key to achieving operational excellence and competitive advantage in today’s fast-paced market.

FAQs

1. What is the primary function of a cassette type single facer machine?

The primary function is to produce corrugated sheets by combining flute-forming and adhesive application processes.

2. How does a cassette type single facer machine improve production efficiency?

It improves efficiency through fast setup times, minimizing downtime, and allowing for high-volume production.

3. Can a cassette type single facer machine handle different packaging sizes?

Yes, these machines are versatile and can accommodate various sizes and types of flutes for different packaging needs.

4. What are the maintenance requirements for a cassette type single facer machine?

Maintenance is straightforward, focusing on regular checks and modular component replacements, ensuring minimal downtime.

5. Are cassette type single facer machines environmentally friendly?

Many modern models are designed to support eco-friendly production practices, making them suitable for sustainable packaging initiatives.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China