Real-Life Success Stories Utilizing Semi-Auto Flute Laminators: Transforming Packaging Efficiency

Jun 26,2025

Real-Life Success Stories Utilizing Semi-Auto Flute Laminators

Introduction to Semi-Auto Flute Laminators

In today’s fast-paced manufacturing landscape, efficiency and quality are paramount. **Semi-auto flute laminators** have emerged as essential tools for businesses seeking to enhance their packaging processes. These machines offer a perfect blend of automation and manual control, allowing com

Real-Life Success Stories Utilizing Semi-Auto Flute Laminators

Introduction to Semi-Auto Flute Laminators

In today’s fast-paced manufacturing landscape, efficiency and quality are paramount. **Semi-auto flute laminators** have emerged as essential tools for businesses seeking to enhance their packaging processes. These machines offer a perfect blend of automation and manual control, allowing companies to achieve high production rates while maintaining flexibility.

This article explores various real-life success stories of companies that have effectively utilized semi-auto flute laminators, showcasing how they have transformed their operations, increased productivity, and improved product quality.

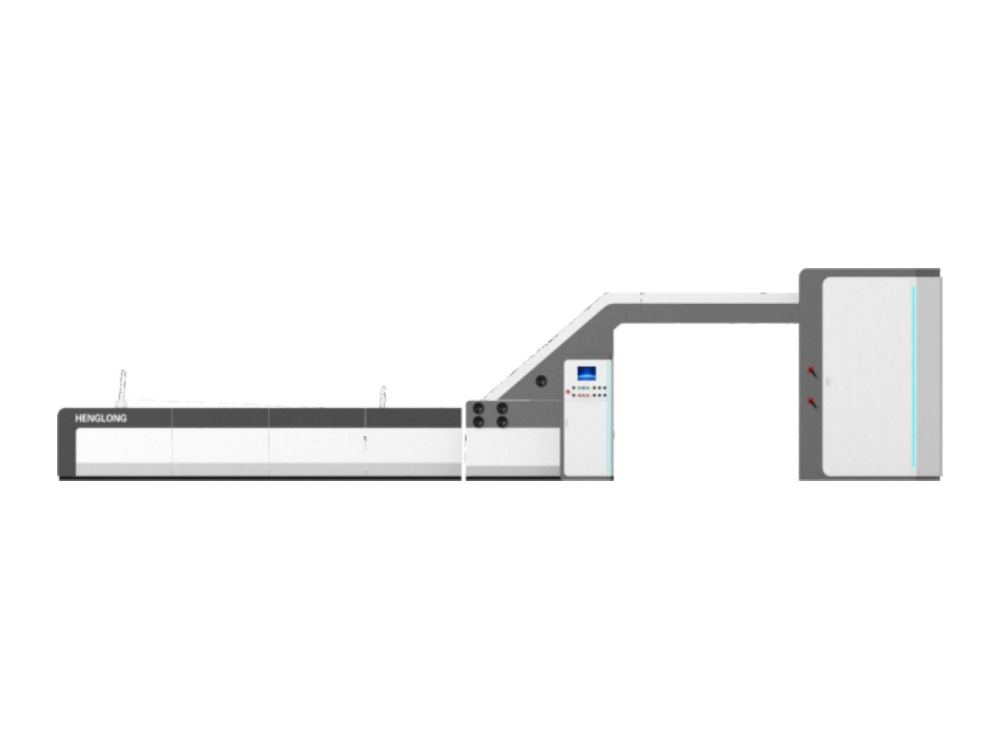

Understanding the Mechanism of Semi-Auto Flute Laminators

Before diving into success stories, it's important to understand how semi-auto flute laminators function. These machines are designed to apply a layer of protective or decorative laminate to corrugated board. The process involves several stages, including feeding, aligning, laminating, and cutting.

Key Features of Semi-Auto Flute Laminators

- **Ease of Operation**: Semi-auto flute laminators are user-friendly, requiring minimal training for operators.

- **Versatility**: These machines can handle various materials and thicknesses, making them suitable for diverse packaging needs.

- **Quality Control**: With built-in calibration systems, these machines ensure consistent quality in every batch produced.

Success Stories from the Industry

Let’s delve into some inspiring case studies that illustrate the transformative power of semi-auto flute laminators.

Case Study 1: A Packaging Company Boosts Production by 50%

A medium-sized packaging company specializing in food products faced challenges with its manual laminating processes. After investing in a semi-auto flute laminator, they reported a **50% increase in production speed**. The operator was able to handle larger volumes without sacrificing quality.

This change not only improved their output but also allowed them to take on more significant contracts, leading to a **30% increase in revenue** within the first year. The management attributed this success to the machine's efficiency and the ability to quickly switch between different packaging sizes.

Case Study 2: Reducing Waste in the Manufacturing Process

Another success story comes from a cosmetics packaging firm that struggled with material waste during the laminating process. By implementing a semi-auto flute laminator, they streamlined their workflow and reduced waste by **40%**.

The precise alignment and speed control of the machine minimized errors, leading to less scrap material. This reduction not only cut costs but also enhanced the company’s sustainability efforts, making them more appealing to environmentally conscious consumers.

Case Study 3: Enhancing Product Quality in Electronics Packaging

A leading electronics manufacturer faced issues with packaging quality, which affected product integrity during shipping. After employing a semi-auto flute laminator, they saw significant improvements in packaging durability.

The laminator provided a consistent finish that protected sensitive components from moisture and damage. As a result, their return rates dropped by **25%**, and customer satisfaction ratings soared. This story exemplifies how semi-auto flute laminators can directly impact product quality and customer trust.

Benefits of Implementing Semi-Auto Flute Laminators

The success stories highlight several critical benefits that businesses can gain from using semi-auto flute laminators.

Increased Efficiency and Productivity

The primary advantage of semi-auto flute laminators is the significant boost in efficiency. With faster processing times and the ability to handle larger volumes, companies can meet tight deadlines and adapt quickly to market demands.

Cost-Effective Solutions

Though the initial investment in a semi-auto flute laminator can be substantial, the long-term savings are undeniable. Reduced labor costs, lower material waste, and improved product quality contribute to a healthier bottom line.

Flexibility and Customization

Semi-auto flute laminators allow companies to customize their packaging solutions based on client specifications. This flexibility helps businesses differentiate themselves in a competitive market, catering to diverse customer needs.

Choosing the Right Semi-Auto Flute Laminator

Not all semi-auto flute laminators are created equal. When selecting the right machine, businesses should consider several factors:

Production Volume Requirements

Assessing the expected production volume is crucial. Companies with high output needs may require more robust models that can handle continuous operations.

Type of Materials Used

Different laminators are designed for specific materials. Ensure the selected machine can accommodate the types of flute and laminate that your business utilizes.

Technical Support and Maintenance

Investing in a semi-auto flute laminator also means considering the availability of technical support and maintenance services. Partnering with a reputable supplier ensures that assistance is readily available in case of technical issues.

Future Trends in Semi-Auto Flute Laminators

As technology continues to evolve, so too will semi-auto flute laminators. Several trends are shaping the future of these machines and the packaging industry as a whole.

Integration of Smart Technology

The future of semi-auto flute laminators lies in the integration of smart technology. Features such as IoT connectivity and predictive maintenance are expected to enhance the operational efficiency and longevity of these machines.

Emphasis on Sustainable Materials

With a growing emphasis on sustainability, manufacturers are exploring eco-friendly laminating materials. Future semi-auto flute laminators will likely be designed to work effectively with biodegradable and recyclable materials.

Adaptation to Market Needs

As consumer preferences shift, the packaging industry must adapt accordingly. Semi-auto flute laminators will evolve to meet the demand for customized packaging solutions, including smaller batch sizes and unique designs.

FAQs about Semi-Auto Flute Laminators

1. What is a semi-auto flute laminator?

A semi-auto flute laminator is a machine that applies laminate to corrugated board, enhancing the quality and durability of packaging products. It combines manual and automated processes for improved efficiency.

2. How does a semi-auto flute laminator improve production efficiency?

By streamlining the laminating process and reducing manual labor, a semi-auto flute laminator speeds up production times and allows for higher volumes of output.

3. What industries benefit from using semi-auto flute laminators?

Industries such as food packaging, electronics, cosmetics, and e-commerce can greatly benefit from the efficiency and quality improvements offered by semi-auto flute laminators.

4. How do I choose the right semi-auto flute laminator for my business?

Consider factors such as production volume, types of materials, and availability of technical support when selecting a semi-auto flute laminator.

5. What are the maintenance requirements for semi-auto flute laminators?

Regular maintenance includes cleaning, lubrication of moving parts, and periodic inspections to ensure optimal performance and longevity of the machine.

Conclusion

Semi-auto flute laminators are changing the landscape of the packaging industry, offering businesses significant advantages in efficiency, cost reduction, and product quality. The success stories shared in this article demonstrate the tangible benefits that can be achieved through the adoption of these machines. As technology progresses, we expect to see even more innovations in semi-auto flute laminators, further enhancing their role in modern manufacturing. Companies that embrace these advancements will undoubtedly gain a competitive edge, ensuring their packaging solutions meet the ever-evolving needs of the market.

TAG:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China