Exploring the Benefits and Features of Semi-Automatic Flute Laminators

Jul 15,2025

Semi-automatic flute laminators are essential machines in the packaging industry, particularly for those involved in producing corrugated board products. These machines are designed to apply a layer of laminate onto fluted substrates, enhancing durability and providing an appealing finish to packaging materials. By streamlining the lamination process, semi-automatic flute laminators significantly

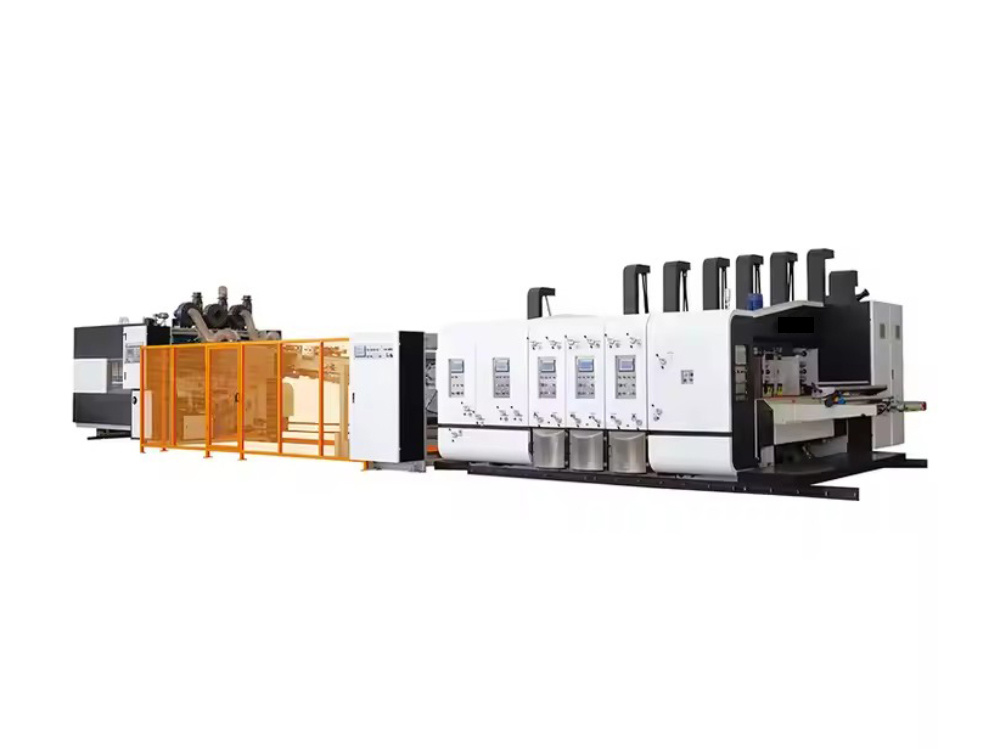

Semi-automatic flute laminators are essential machines in the packaging industry, particularly for those involved in producing corrugated board products. These machines are designed to apply a layer of laminate onto fluted substrates, enhancing durability and providing an appealing finish to packaging materials. By streamlining the lamination process, semi-automatic flute laminators significantly improve operational efficiency, making them an attractive choice for manufacturers seeking to optimize their production lines.

One of the primary benefits of using a semi-automatic flute laminator is the balance it strikes between manual and fully automatic operations. Unlike fully automatic systems that require minimal human intervention, semi-automatic machines still allow operators to exercise control over the lamination process. This flexibility is particularly beneficial in production environments where batches of varying sizes or specifications are common. Operators can easily adjust settings, monitor quality, and intervene when necessary, thereby ensuring consistent output.

The technology behind semi-automatic flute laminators typically includes advanced feeding systems, precision alignment mechanisms, and adjustable pressure controls. These features work together to ensure that the laminate is applied evenly and securely to the substrate, which is crucial for maintaining the integrity of the finished product. Additionally, many models offer quick-change capabilities, allowing operators to swiftly switch between different laminate types or thicknesses, thereby reducing downtime and maximizing productivity.

In terms of quality, the use of a semi-automatic flute laminator can lead to superior adhesion and finish compared to manual processes. This is particularly important for products that require a professional appearance or need to withstand handling and transportation. The enhanced quality control that semi-automatic machines provide contributes to overall customer satisfaction, as clients receive consistent and reliable packaging solutions.

Moreover, semi-automatic flute laminators can integrate with other machinery within a production line, such as die-cutters or folding machines. This compatibility allows for a seamless workflow, improving the overall efficiency of the manufacturing process. By reducing the time between steps, manufacturers can increase their throughput and meet tighter delivery schedules.

In conclusion, semi-automatic flute laminators present a compelling option for businesses in the packaging industry. Their blend of automation and operator control, coupled with advanced technology, makes them a valuable asset for enhancing productivity and product quality. For manufacturers looking to elevate their packaging solutions, investing in a semi-automatic flute laminator may prove to be a strategic move that yields significant returns. Understanding the features and benefits of these machines can help clients make informed decisions that align with their operational goals.

One of the primary benefits of using a semi-automatic flute laminator is the balance it strikes between manual and fully automatic operations. Unlike fully automatic systems that require minimal human intervention, semi-automatic machines still allow operators to exercise control over the lamination process. This flexibility is particularly beneficial in production environments where batches of varying sizes or specifications are common. Operators can easily adjust settings, monitor quality, and intervene when necessary, thereby ensuring consistent output.

The technology behind semi-automatic flute laminators typically includes advanced feeding systems, precision alignment mechanisms, and adjustable pressure controls. These features work together to ensure that the laminate is applied evenly and securely to the substrate, which is crucial for maintaining the integrity of the finished product. Additionally, many models offer quick-change capabilities, allowing operators to swiftly switch between different laminate types or thicknesses, thereby reducing downtime and maximizing productivity.

In terms of quality, the use of a semi-automatic flute laminator can lead to superior adhesion and finish compared to manual processes. This is particularly important for products that require a professional appearance or need to withstand handling and transportation. The enhanced quality control that semi-automatic machines provide contributes to overall customer satisfaction, as clients receive consistent and reliable packaging solutions.

Moreover, semi-automatic flute laminators can integrate with other machinery within a production line, such as die-cutters or folding machines. This compatibility allows for a seamless workflow, improving the overall efficiency of the manufacturing process. By reducing the time between steps, manufacturers can increase their throughput and meet tighter delivery schedules.

In conclusion, semi-automatic flute laminators present a compelling option for businesses in the packaging industry. Their blend of automation and operator control, coupled with advanced technology, makes them a valuable asset for enhancing productivity and product quality. For manufacturers looking to elevate their packaging solutions, investing in a semi-automatic flute laminator may prove to be a strategic move that yields significant returns. Understanding the features and benefits of these machines can help clients make informed decisions that align with their operational goals.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China