The Essential Guide to Semi-Auto Flute Laminators for Startups

Jul 20,2025

The Essential Guide to Semi-Auto Flute Laminators for Startups

Table of Contents

1. Introduction to Semi-Auto Flute Laminators

2. What is a Semi-Auto Flute Laminator?

3. Benefits of Using Semi-Auto Flute Laminators for Startups

4. Key Features to Consider When Choosing a Semi-Auto Flute Laminator

5. Applications of Semi-Auto Flute Laminators in Various Industries

6. How to

The Essential Guide to Semi-Auto Flute Laminators for Startups

Table of Contents

- 1. Introduction to Semi-Auto Flute Laminators

- 2. What is a Semi-Auto Flute Laminator?

- 3. Benefits of Using Semi-Auto Flute Laminators for Startups

- 4. Key Features to Consider When Choosing a Semi-Auto Flute Laminator

- 5. Applications of Semi-Auto Flute Laminators in Various Industries

- 6. How to Maintain Your Semi-Auto Flute Laminator for Longevity

- 7. Cost Analysis and Investment Considerations

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Semi-Auto Flute Laminators

In today's competitive market, startups in the manufacturing and packaging industries are increasingly looking for efficient solutions to enhance productivity and reduce costs. **Semi-auto flute laminators** are a valuable asset for businesses aiming to improve their packaging processes. These machines combine efficiency with ease of use, making them an ideal choice for startups navigating the complexities of production.

2. What is a Semi-Auto Flute Laminator?

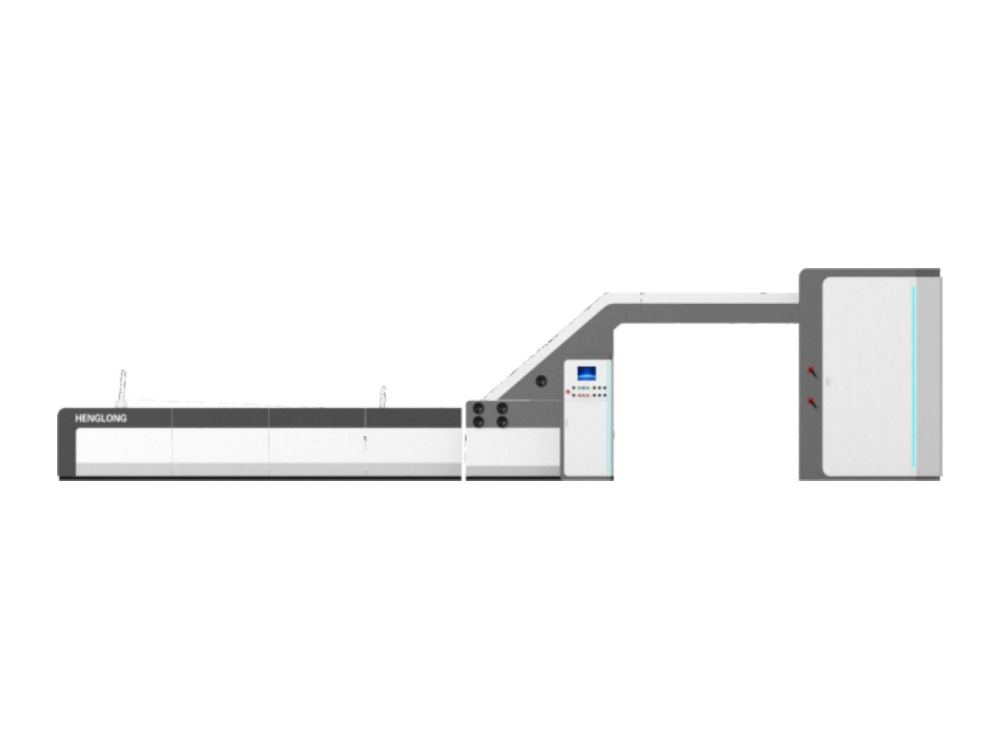

A semi-auto flute laminator is a machine designed to apply a laminate layer to the fluted surfaces of corrugated cardboard. This process not only enhances the aesthetic appeal of the packaging but also adds durability and strength. Unlike fully automatic laminators, semi-auto models require some manual intervention, allowing operators to maintain control over specific aspects of the production process.

The Working Mechanism of Semi-Auto Flute Laminators

The operation of a semi-auto flute laminator involves several steps:

- **Feeding the material**: The operator manually feeds the fluted cardboard into the machine.

- **Applying the laminate**: The machine uses rollers to apply adhesive and laminate film onto the surface.

- **Pressing**: The laminated material is pressed to ensure proper adhesion and finish.

- **Cutting**: Finally, the laminated sheets are cut into required sizes, ready for packaging.

3. Benefits of Using Semi-Auto Flute Laminators for Startups

Investing in a semi-auto flute laminator can provide numerous advantages for startups. Here are some key benefits:

Cost Efficiency

Semi-auto models are often more affordable than their fully automatic counterparts. This makes them an attractive option for startups with limited budgets.

Enhanced Control

With a semi-auto laminator, operators can monitor and adjust processes in real-time, ensuring high-quality output. This level of control can lead to fewer errors and less waste.

Versatility

Semi-auto flute laminators can handle various materials and applications, allowing startups to diversify their product offerings without needing multiple machines.

Space Saving

These machines typically have a smaller footprint compared to fully automatic models, making them suitable for startups operating in limited spaces.

4. Key Features to Consider When Choosing a Semi-Auto Flute Laminator

When selecting a semi-auto flute laminator, several features should be taken into account:

Speed and Efficiency

The speed of the laminator can significantly impact production rates. Look for machines that offer adjustable speeds to match your production demands.

Material Compatibility

Ensure that the laminator can handle the specific types of materials you plan to use. Compatibility with various laminating films is essential for versatility.

Ease of Use

A user-friendly interface will reduce the learning curve for new operators. Look for machines that offer clear controls and easy setup.

Durability and Build Quality

Invest in a machine built from high-quality materials to withstand the rigors of daily use. A robust construction will translate to lower maintenance costs over time.

Maintenance Requirements

Consider how much maintenance the machine requires. A model that is easy to clean and service will save time and improve productivity.

5. Applications of Semi-Auto Flute Laminators in Various Industries

Semi-auto flute laminators are utilized across many industries due to their versatility. Here are some common applications:

Food Packaging

In the food industry, laminated packaging helps preserve freshness and protect products from contamination.

Consumer Goods

Retail packaging for consumer products often requires aesthetic appeal, making laminators essential for creating eye-catching designs.

Electronics Packaging

Laminated packaging provides extra protection for sensitive electronic components, reducing the risk of damage during transit.

Cosmetics and Personal Care

High-quality packaging is critical in the cosmetics industry, and laminated materials can enhance product presentation.

6. How to Maintain Your Semi-Auto Flute Laminator for Longevity

Maintaining your semi-auto flute laminator is crucial for ensuring its longevity and optimal performance. Here are some essential maintenance tips:

Regular Cleaning

Keep the machine clean by regularly removing adhesive residues and dust. This will prevent malfunctions and ensure smooth operation.

Routine Inspections

Conduct periodic inspections to identify and address any wear and tear. Look for signs of damage to belts, rollers, and electrical components.

Lubrication

Ensure that all moving parts are properly lubricated to reduce friction and prolong the machine's life.

Training Operators

Proper training for operators minimizes the risk of misuse, which can lead to premature wear or accidents.

7. Cost Analysis and Investment Considerations

When considering the purchase of a semi-auto flute laminator, a thorough cost analysis is critical. Startups should evaluate both the initial investment and the long-term operational costs.

Initial Investment

The cost of semi-auto flute laminators can vary widely based on features, brand, and specifications. It's vital to select a machine that aligns with your budget and production needs.

Operational Costs

Factor in ongoing costs such as materials, maintenance, and labor. Understanding these expenses will help you assess the overall return on investment.

Financing Options

Explore financing options available for purchasing equipment. Many manufacturers offer leasing plans that can reduce upfront costs while allowing access to high-quality machinery.

8. Frequently Asked Questions

What is the difference between semi-auto and fully automatic flute laminators?

Semi-auto laminators require some manual intervention, whereas fully automatic models operate independently once set up. Semi-auto laminators often have a lower initial cost and are easier to operate.

Can semi-auto flute laminators handle different material types?

Yes, many semi-auto flute laminators are designed to work with various materials, including different types of laminating films and corrugated cardboard.

How much maintenance do semi-auto flute laminators require?

Maintenance requirements can vary, but regular cleaning, lubrication, and inspections will help keep the machine in good condition and extend its lifespan.

What is the average production speed of a semi-auto flute laminator?

Production speeds can vary based on the model and material, but many semi-auto flute laminators can achieve speeds of up to 30 meters per minute.

Are there financing options available for purchasing a semi-auto flute laminator?

Yes, many manufacturers and dealers offer financing options to make it easier for startups to invest in necessary equipment.

9. Conclusion

In conclusion, **semi-auto flute laminators** offer startups a viable solution for enhancing their packaging processes. With a range of benefits, including cost efficiency, versatility, and improved quality control, these machines are an essential investment for businesses looking to thrive in today's competitive landscape. By carefully selecting the right laminator and implementing proper maintenance practices, startups can optimize their production and set the stage for future growth.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China