Maximizing Efficiency with Precision Slitter Scorers in Production Lines

Aug 23,2025

Maximizing Efficiency with Precision Slitter Scorers in Production Lines

Table of Contents

1. Introduction to Precision Slitter Scorers

2. Understanding Slitter Scorers: What Are They?

3. Key Benefits of Precision Slitter Scorers in Production

4. How Precision Slitter Scorers Work in Manufacturing

5. Industries That Benefit from Slitter Scorers

6. Best Practices for Im

Maximizing Efficiency with Precision Slitter Scorers in Production Lines

Table of Contents

- 1. Introduction to Precision Slitter Scorers

- 2. Understanding Slitter Scorers: What Are They?

- 3. Key Benefits of Precision Slitter Scorers in Production

- 4. How Precision Slitter Scorers Work in Manufacturing

- 5. Industries That Benefit from Slitter Scorers

- 6. Best Practices for Implementing Precision Slitter Scorers

- 7. Maintaining Precision Slitter Scorers for Longevity

- 8. Future Trends in Slitter Scoring Technology

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion: The Path to Enhanced Efficiency

1. Introduction to Precision Slitter Scorers

In the ever-evolving landscape of manufacturing, efficiency is paramount. **Precision slitter scorers** serve as a cornerstone for organizations looking to optimize their production lines. These machines are designed to cut and score materials with unmatched accuracy, significantly reducing waste and increasing throughput. In this article, we will delve deep into the world of slitter scorers, exploring their functionalities, advantages, and the best practices for their integration into production lines.

2. Understanding Slitter Scorers: What Are They?

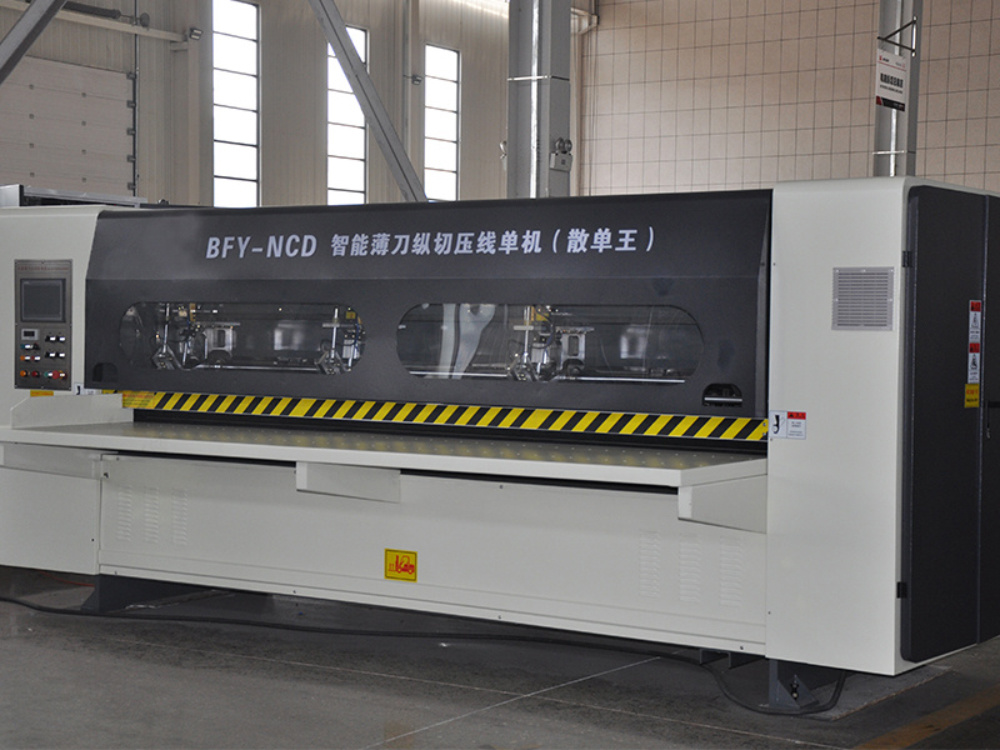

Precision slitter scorers are specialized machines that perform intricate cutting and scoring tasks on various materials, including paper, film, and foil. Unlike traditional cutting tools, slitter scorers ensure clean and precise cuts, minimizing the likelihood of tearing or fraying. These machines utilize razor-sharp blades that operate at high speeds, delivering optimal performance in high-volume production environments.

Types of Slitter Scorers

Precision slitter scorers come in various types, each tailored to meet specific production needs. The most common types include:

- Rotary Slitter Scorers: Ideal for continuous rolls of material, rotary scorers provide smooth and efficient cutting.

- Flatbed Slitter Scorers: Designed for sheet materials, flatbed scorers ensure precision in both cutting and scoring.

- Vertical Slitter Scorers: These machines are often used for thicker materials, providing robust cutting capabilities.

3. Key Benefits of Precision Slitter Scorers in Production

Integrating precision slitter scorers into your production line offers numerous advantages that can significantly enhance operational efficiency.

Enhanced Cutting Accuracy

Precision slitter scorers deliver unparalleled accuracy, ensuring that cuts are made to exact specifications. This accuracy minimizes the need for rework, saving time and resources.

Reduced Material Waste

By producing cleaner cuts, slitter scorers help reduce material waste, allowing manufacturers to maximize their material usage and lower production costs.

Improved Production Speed

With the ability to operate at high speeds, precision slitter scorers can significantly increase production rates. This efficiency contributes to faster turnaround times and improved customer satisfaction.

Versatility in Material Handling

Slitter scorers are versatile machines capable of handling a wide range of materials, from thin films to thicker substrates. This adaptability makes them suitable for various industries.

4. How Precision Slitter Scorers Work in Manufacturing

Understanding the operational mechanics of precision slitter scorers is essential for maximizing their potential. These machines utilize a combination of sharp blades and rollers to achieve precise cuts.

The Cutting Process

1. **Material Loading:** The material is fed into the slitter scorer through rollers.

2. **Scoring:** The scoring blades create indentations, which guide the cutting process.

3. **Cutting:** The sharp blades slice through the material, following the scored lines for accuracy.

4. **Material Collection:** Finished products are collected for further processing or packaging.

Automation and Control Systems

Modern slitter scorers are equipped with advanced automation and control systems, allowing for real-time monitoring and adjustments. This technology enhances precision and reduces the likelihood of human error.

5. Industries That Benefit from Slitter Scorers

Precision slitter scorers are invaluable across various industries, providing tailored solutions to meet unique production requirements.

Packaging Industry

In the packaging sector, precision slitter scorers are essential for producing boxes, labels, and flexible packaging. Their ability to handle diverse materials makes them a staple in the industry.

Textile Industry

Textile manufacturers use slitter scorers to cut and score fabrics, ensuring precise dimensions for garments and other textile products.

Electronics Industry

For the electronics sector, precision slitter scorers are crucial in producing components like circuit boards, where accuracy is paramount.

6. Best Practices for Implementing Precision Slitter Scorers

To fully leverage the capabilities of precision slitter scorers, manufacturers should adhere to several best practices.

Conducting a Needs Assessment

Before integrating slitter scorers into your production line, conduct a thorough needs assessment to determine the specific capabilities required.

Training Operators

Invest in comprehensive training for operators to ensure they understand the machine's functionality and can troubleshoot issues effectively.

Regular Maintenance Checks

Establish a routine maintenance schedule to keep machinery in optimal condition, minimizing downtime and extending the lifespan of the equipment.

7. Maintaining Precision Slitter Scorers for Longevity

Proper maintenance is vital for ensuring the longevity and efficiency of precision slitter scorers.

Daily Operational Checks

Operators should perform daily checks for any signs of wear or damage to blades, belts, and other components.

Scheduled Overhauls

Implement scheduled overhauls to conduct more in-depth inspections and replacements of worn parts.

8. Future Trends in Slitter Scoring Technology

As technology advances, precision slitter scorers will continue to evolve, offering even greater efficiency and versatility.

Integration with Industry 4.0

The rise of Industry 4.0 will lead to more interconnected slitter scoring systems, allowing for enhanced data analytics and real-time monitoring.

Eco-Friendly Innovations

Future developments may include more sustainable materials and processes, reducing the environmental impact of slitting operations.

9. Frequently Asked Questions (FAQs)

What materials can precision slitter scorers handle?

Precision slitter scorers can cut and score a variety of materials, including paper, film, foil, and textiles.

How do I choose the right slitter scorer for my production line?

Consider factors such as material type, production volume, and specific cutting requirements when selecting a slitter scorer.

What is the typical lifespan of a precision slitter scorer?

With proper maintenance, a precision slitter scorer can last several years, with many manufacturers reporting lifespans of 10 years or more.

Can slitter scorers be automated?

Yes, many modern slitter scorers come equipped with automation features for enhanced efficiency and precision.

Are there any safety considerations when operating slitter scorers?

Yes, operators should always follow safety protocols, including wearing protective gear and ensuring proper training on machine operation.

10. Conclusion: The Path to Enhanced Efficiency

In conclusion, **precision slitter scorers** are essential tools for manufacturers aiming to maximize efficiency and accuracy in their production lines. By understanding their functionality, benefits, and maintenance requirements, companies can leverage these machines to enhance their operations significantly. As technology continues to advance, embracing innovations in slitter scoring will be crucial for staying competitive in the dynamic manufacturing landscape. Implementing best practices and maintaining the equipment will ensure that your production line runs smoothly and effectively, leading to enhanced productivity and reduced costs.

TAG:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China