Understanding Semi-Auto Flute Laminators: A Key Player in Packaging Machinery

Sep 07,2025

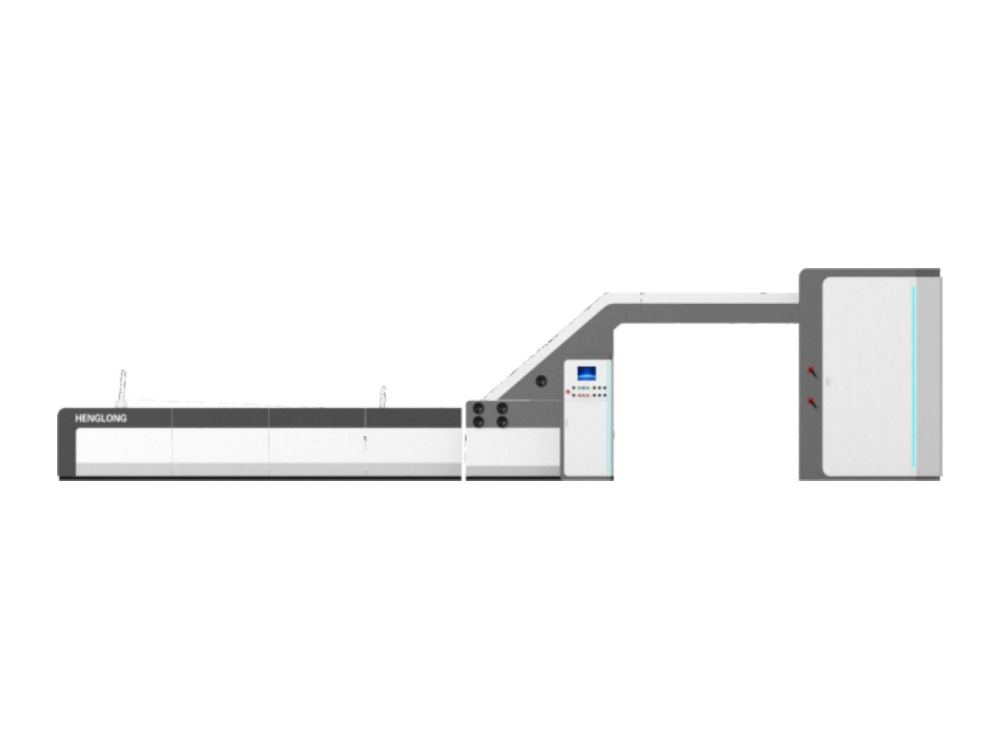

Semi-auto flute laminators are specialized machines designed for the lamination of flute boards, which are widely used in packaging. These laminators combine the benefits of manual and automatic processes, allowing operators to maintain control while enjoying increased efficiency. The semi-automatic nature means that certain tasks, such as feeding the material and adjusting settings, may require m

Semi-auto flute laminators are specialized machines designed for the lamination of flute boards, which are widely used in packaging. These laminators combine the benefits of manual and automatic processes, allowing operators to maintain control while enjoying increased efficiency. The semi-automatic nature means that certain tasks, such as feeding the material and adjusting settings, may require manual input, whereas other processes are automated, contributing to a streamlined workflow.

One of the primary advantages of semi-auto flute laminators is their versatility. They can handle various materials, including paper, cardboard, and thin plastics. This adaptability makes them suitable for producing a wide range of packaging solutions, such as boxes, displays, and protective packaging. The ability to laminate different substrates ensures that manufacturers can meet diverse client needs without investing in multiple machines.

The laminating process itself involves applying a layer of adhesive between the flute board and the outer material. This not only enhances the aesthetic appeal of the packaging but also adds durability and strength, ensuring the final product can withstand handling and transportation. The quality of lamination is crucial, as it affects the overall performance of the packaging. With semi-auto flute laminators, operators can achieve a consistent and high-quality finish, thereby reducing waste and increasing production efficiency.

When considering a semi-auto flute laminator, it's important to focus on key operational features. These machines often come equipped with adjustable speed settings, allowing operators to modify the lamination speed based on the material being processed. Additionally, many models provide user-friendly interfaces that simplify operation and reduce the learning curve for new employees.

Regular maintenance is vital for ensuring the longevity and optimal performance of semi-auto flute laminators. Operators should be trained to perform routine checks and cleanings, as well as to identify potential issues before they escalate. Proper maintenance not only prolongs the lifespan of the machine but also guarantees consistent output quality.

In summary, semi-auto flute laminators play a crucial role in the packaging machinery sector by offering a balance of manual control and automated efficiency. Their ability to handle various materials and produce high-quality laminated products makes them invaluable for manufacturers looking to enhance their packaging solutions. By understanding their functionalities and operational considerations, professionals can leverage these machines to improve productivity and meet the evolving demands of the packaging industry.

One of the primary advantages of semi-auto flute laminators is their versatility. They can handle various materials, including paper, cardboard, and thin plastics. This adaptability makes them suitable for producing a wide range of packaging solutions, such as boxes, displays, and protective packaging. The ability to laminate different substrates ensures that manufacturers can meet diverse client needs without investing in multiple machines.

The laminating process itself involves applying a layer of adhesive between the flute board and the outer material. This not only enhances the aesthetic appeal of the packaging but also adds durability and strength, ensuring the final product can withstand handling and transportation. The quality of lamination is crucial, as it affects the overall performance of the packaging. With semi-auto flute laminators, operators can achieve a consistent and high-quality finish, thereby reducing waste and increasing production efficiency.

When considering a semi-auto flute laminator, it's important to focus on key operational features. These machines often come equipped with adjustable speed settings, allowing operators to modify the lamination speed based on the material being processed. Additionally, many models provide user-friendly interfaces that simplify operation and reduce the learning curve for new employees.

Regular maintenance is vital for ensuring the longevity and optimal performance of semi-auto flute laminators. Operators should be trained to perform routine checks and cleanings, as well as to identify potential issues before they escalate. Proper maintenance not only prolongs the lifespan of the machine but also guarantees consistent output quality.

In summary, semi-auto flute laminators play a crucial role in the packaging machinery sector by offering a balance of manual control and automated efficiency. Their ability to handle various materials and produce high-quality laminated products makes them invaluable for manufacturers looking to enhance their packaging solutions. By understanding their functionalities and operational considerations, professionals can leverage these machines to improve productivity and meet the evolving demands of the packaging industry.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China