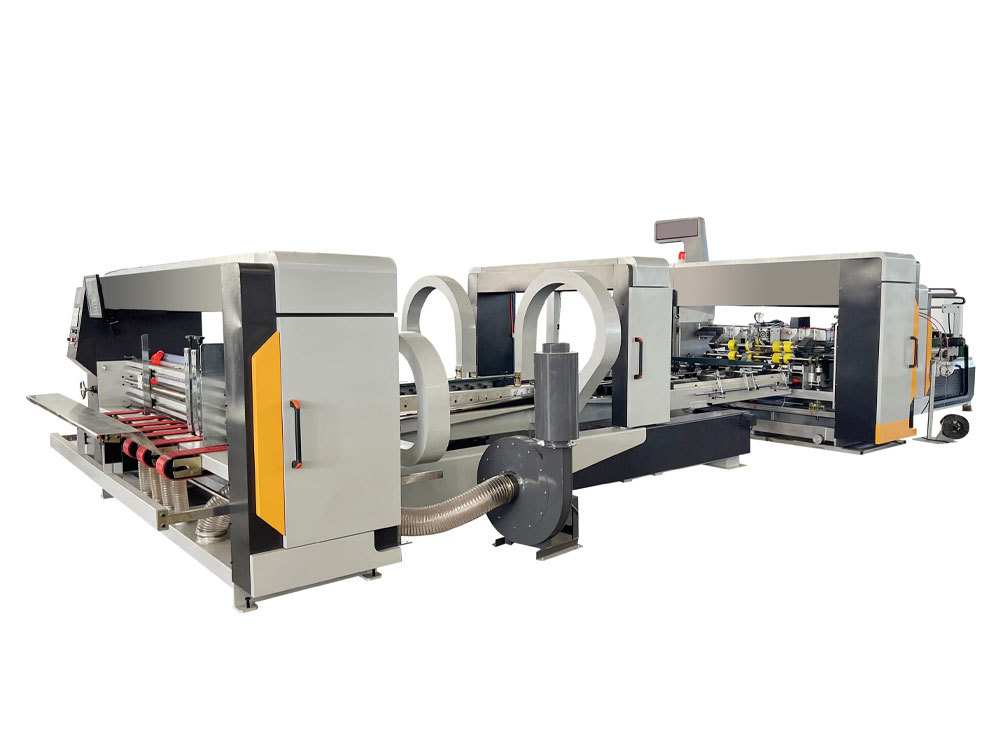

Corrugated cardboard production line

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

Product parameter

No. Technology project Five Layers Three Layers 1 Maximum production width 1800 mm 1800mm 2 Design speed 150 m/min 120m/min 3 Economic speed 100-120 m/min 60-100 m/min 4 Commissioning temperature ≥175 ℃ ≥172 ℃ 5 Base paper grades ≥level B ≥level B 6 Base paper moisture content 10%±2% 11%±2% 7 Tissue 100~250g/m² 100~180g/m² 8 The core of paper 100~250g/m² 80~160g/m² 9 Tile paper 100- 200g/m² 90~160g/m² 10 Corrugated type combination A, B, C, E

(customer can customize)A, B, C, E

(customer can customize)11 Maximum steam pressure 16Kg/cm² 16kg/cm² 12 Common steam pressure 10-12Kg/cm² 8-12kg/cm² 13 The total amount of steam 2500-3000KG/h 1000-1500KG/h 14 Compressed air pressure

is commonly used0.8-1.1Mpa(4-8kg/cm² ) 5-7kg/cm² 15 Maximum

compressed air pressure1.2Mpa(9kg/cm² ) 8kg/cm² 16 Overall

compressed air consumptionAbout after 1 m³/min 1 m³/min 17 The power supply 380V, 50HZ,

three-phase four-wire system

(foreign voltage can be customized)380V 50Hz

Three-phase four-wire system

(foreign voltage can be customized)18 Total installed power

of equipmentAbout 220 KW About 120KW 19 Actual electricity

consumptionAbout 150KW(full speed) About 80KW(full speed) 20 Equipment cover area About 70m x 10m x 4.5m

(the specific length is subject

to the foundation drawing)About 45m×8m×4.5m

(The specific length shall be subject

to the foundation diagram)21 Forecast production Output of about

6-70,000 square meters in 8 hours22 Paper outlet direction

of the deviceAccording to the user workshop

to determine the left or right driveAccording to the user workshop

to determine the left or right drive23 Suitability of equipment Available A, B, C

grade domestic base paper

or imported base paperavailable A, B, C

grade domestic base paper

or imported base paper.If there is any other technical correction, no further notice will be given Production process

Sample dispaly

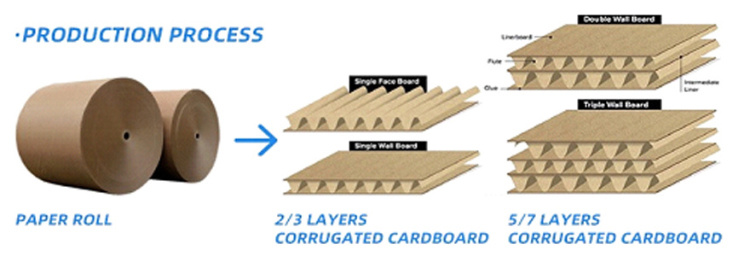

Corrugated cardboard production line is a key equipment combination for manufacturing corrugated cardboard.

1. Basic composition and workflow

Base paper rack

The starting part of the corrugated cardboard production line is the base paper rack, which can hold base paper rolls of different specifications. The base paper rack is equipped with a tension control system, which can ensure the stability of the tension of the base paper during transportation and prevent the paper from being loose or overly tight, which is crucial to the subsequent molding quality of the corrugated cardboard.

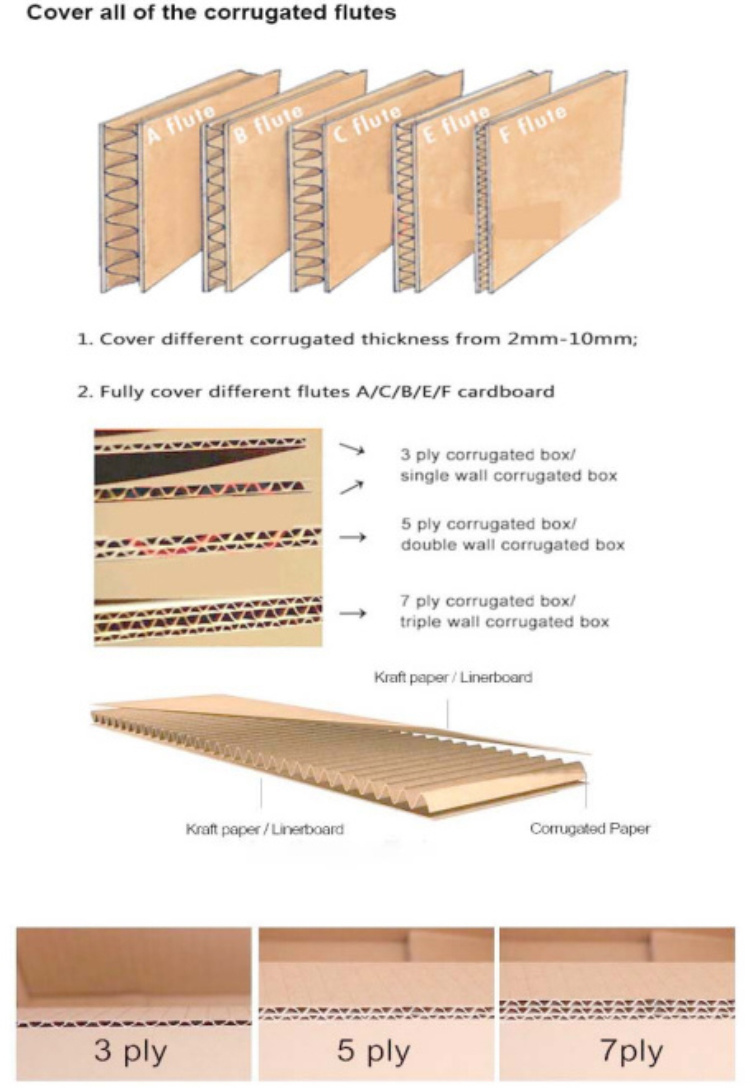

Corrugated roller part

This is one of the core areas of the production line. Through the extrusion of the upper and lower corrugated rollers, the base paper is processed into corrugated paper with a specific flute type (such as A flute, B flute, C flute, etc.). The corrugated roller has very high precision, and the flute shape on its surface is accurate, ensuring that the parameters such as flute height and flute spacing of the produced corrugated paper meet the standards, thereby affecting the strength and cushioning performance of the corrugated cardboard.

Gluing device

Responsible for evenly applying glue to corrugated paper and other papers. Accurate glue application control can ensure the bonding firmness of the corrugated cardboard. Too little glue will cause the cardboard to delaminate, while too much glue will cause waste and may affect the appearance and flatness of the cardboard.

Composite and drying section

The glued corrugated paper and other papers are composited here to form corrugated cardboard. Then it enters the drying area, where the glue is quickly dried by heating, ventilation, etc., so that the corrugated cardboard is quickly shaped and the production efficiency is improved.

2. Performance characteristics

Efficient production

The corrugated cardboard production line has a high production speed and can meet the needs of large-scale production. It can produce a large amount of corrugated cardboard with stable quality in a short time.

Stable quality

Due to the precise control of each link, such as tension control, flute type forming, glue coating control, etc., the quality of the corrugated cardboard produced is stable, and it can meet high standards in thickness, strength, flatness, etc.

Flexibility

According to market demand, by adjusting equipment parameters, corrugated cardboard with different flute combinations and different thicknesses can be produced to meet the packaging industry's needs for various product packaging.

Corrugated cardboard production line occupies an indispensable position in the modern packaging industry, providing reliable material production guarantee for the safe transportation and packaging of many products.

Corrugated cardboard production line

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.