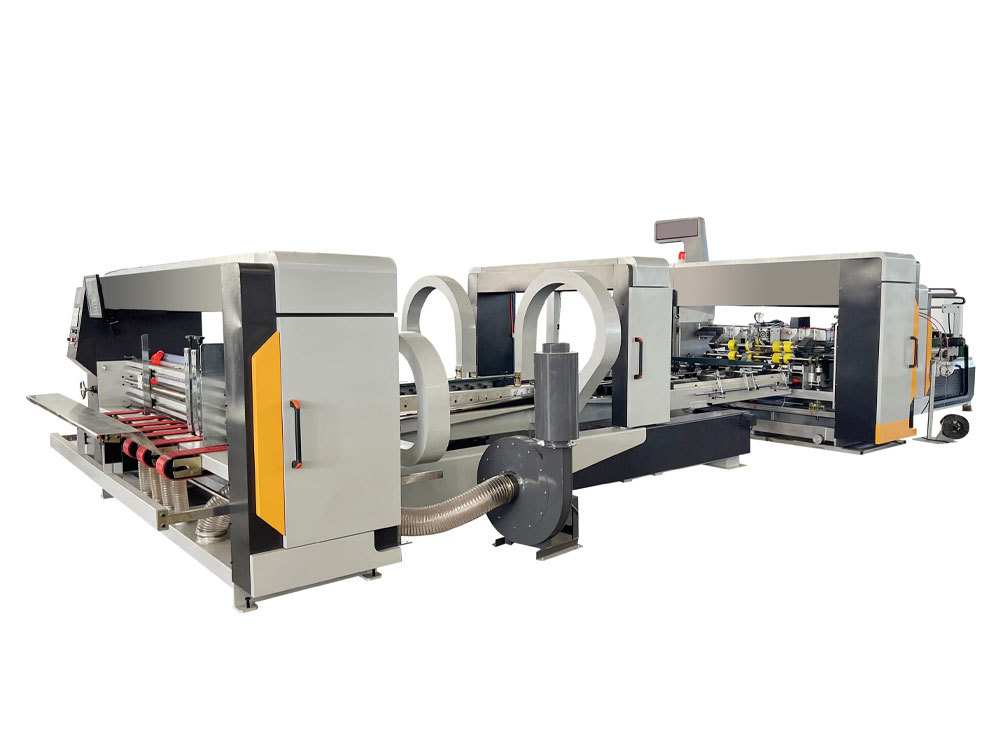

Semiauto corrugated cardboard carton box flexo printing slotting die-cutting machinery

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

Product introduction

1. The machine adopts chain paper feeding mode.

2. Each unit adopts electric opening and closing, pneumatic locking, pneumatic lifting plate, automatic ink distribution and pneumatic brake split positioning.

3. The phase of printing shaft and die-cutting roller is adjusted by electric 360degrees..

4. The lubrication mode adopts double oil pumps, automatic spraying and circulating oil supply.

5. The shaft and roller of the machine are ground and plated with hard chromium.

6. Siemens, Schneider and other international well-known brands are used for Electro mechanical.

7. The bearing of this machine adopts famous brand.

8. The hanging plate can be selected, and the mesh of anilox roller can be 180-250 mesh.

Product parameters

Model WB-A2400 WB-B2600 WB-C2800 WB-D3000 Max cardboard size(mm) 2200x900 2400x1200 2600x1400 2800x1600 Min cardboard size (mm) 300x600 350x600 400x600 420x600 Max printing size(mm) 2100x900 2300x900 2500x1400 2700x1600 Max speed (pcs/min) 80 60 60 60 Max slotting depth(mm) 220 300 350 400 Printing roller diamater(mm) 300 405 480 530 Printing plate THK(mm) 4-7 4-7 4-7 4-7 Printing colors optional 1-6 1-6 1-6 1-6 Product details

Printing unit

1. Printing phase electric digital 360 degree adjustment (both operation and stop can be adjusted).

2. The printing roller is equipped with plate hanging groove to load and unload the printing plate. The forward and reverse directions are electrically controlled by the foot switch.

3. Manually adjust the gap dial of the paper feeding roller, with the adjustment range of 0-12mm.

4. Printing phase electric digital 360 degree adjustment (both operation and stop can be adjusted).

5. Pneumatic diaphragm pump, stable ink supply, convenient and fast operation and maintenance.

6. The printing phase is fixed and equipped with cylinder brake device. Keep the original gear position fixed point.

Die cutting unit

1.Rubber roller: centrifugal casting steel cylinder. The rubber pad adopts German brand.

2. The rubber pad of die-cutting roll adopts German brand.

3. Die cutting roller phase and axial adjustment, PLC touch screen control, electric digital 360 degree adjustment.

4. The rubber pad roller is a cutting and repairing mechanism, and the rubber pad can be reused for many times.

5. The differential compensation device can automatically adjust the number of revolutions of the rubber buffer roll.

6. The mechanical transverse ± 40mm swimming device of rubber cushion roller improves the service life of die-cutting rubber cushion.

Pre feeder unit

Paper transport machine is aim at cardboard boxfactow

OriginaI chain the cardboard box which send paper printing.The large quantity quantity produce development produce of continuous lose a paper equipment change artificial thus list Zhang Song4 Zhi3 for con-continuous send paper assurance the carton walk positive not only exaltation work efficiency and the first mate lower a worker labor strength.again lower to discard an article rate.Stacker

1. The paper receiving arm can be operated manually or automatically, and a safety mechanism is set to prevent the paper receiving arm from falling suddenly.

2. The lifting of the bed table is driven by a strong chain.

3. The stacking height is 1600mm.

4. The bed table automatically adjusts the tilt with the stacking height of paperboard, high speed, lifting motor, with braking function.

5. Pneumatic paper lifting mechanism, when the paperboard is stacked to a predetermined height, the paper receiving support plate will automatically open and the support will hold the paperboard.

6. Flat wrinkled belt to prevent cardboard from sliding.

Semiauto corrugated cardboard carton box flexo printing slotting die-cutting machinery

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.