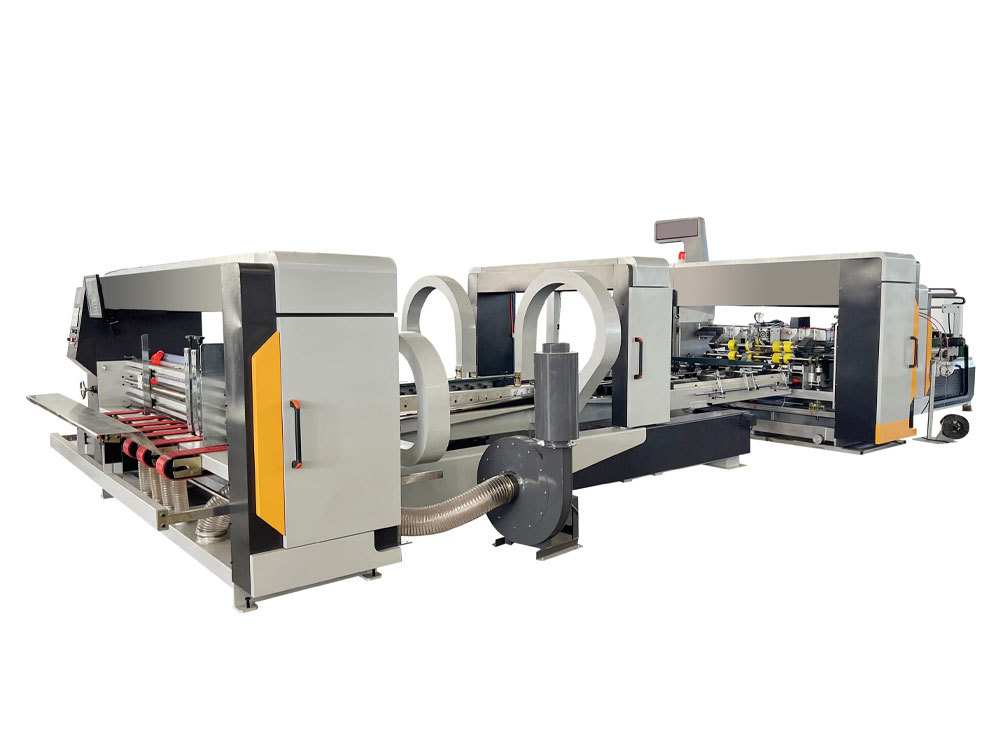

Semiauto corrugated cardboard carton box flexo printing slotting die-cutting machinery

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

Main units and functional characteristics

Hydraulic shaftless paper holder

Main function: The hydraulic shaftless paper holder realizes the functions of raw paper installation, adjustment, tension control, and convenient paper replacement in the whole machine.

1.The support arm is equipped with an operation panel, which can easily and conveniently control the movement and lifting of the support arm through buttons, independent hydraulic system, and scale bar to achieve the function of clamping and adjusting the raw paper.

2. The pressure regulating valves and switches on both sides accurately and uniformly control the tension of the paper and provide convenient paper changing functions.

3. Simple structure, high-quality materials, solid workmanship, mature craftsmanship, stable performance, and long service life.Core paper gluing unit

Main function: Each set of fixed adhesive lines in the core paper coating unit is adjustable, and the rubber rollers are fixed to ensure the accuracy of the adhesive lines. Each model requires a set of glue coating machines.

1. Fully automatic glue supply detection system, automatic gluing, adding glue, automatic/manual switching, reduces manual operation, facilitates maintenance and cleaning, and improves work efficiency.

2. Changing specifications by winding paper with different gluing units is easy to operate, with high precision and stable performance.

3. The swing arm system can quickly detach through the side air valve, and maintenance and inspection during shutdown will not cause damage to the paper, making it simple and efficient.

4. Stretch the transition roller, specific patterns can evenly pull the paper horizontally, and roll the paper flat.Compression unit

Main function: Multi layer tile paper composite roller and belt press tightly together, firmly bonded.

1. The floating installation of the pressure roller requires no adjustment, increasing the adhesive strength of the paper.

2. By increasing the pressing time with compression, the composite efficiency can be improved.Drying unit

Main function: Drying excess moisture in composite paper to improve cutting efficiency.

1. The circular arc heating structure is simple and the paper feeding operation is easy.

2. The heating adopts electromagnetic heating, which heats up quickly, heats up at a high temperature, heats evenly and stably, controls the system, and is easy to operate.Composite core paper gluing unit

Main function: Glue coating on composite paper

1. The overall lateral movement of the gluing unit facilitates the adjustment of glue line misalignment and gluing.

2. The three roll transfer of the glue roller is convenient for adjusting and controlling the amount of glue.High speed cross cutting machine

Main function: Formation of continuous honeycomb paper cores with a thickness specification of 8-80mm.

1. The cast body has good load-bearing capacity, mature technology, and is not easily deformed.

2. The power structure is simple, suitable for high-speed production, and easy to maintain.

3. High speed servo feeding system with stable performance and high precision.

4. Independent oil lubrication system, continuous automatic lubrication, maintaining high-speed production rhythm.

5. Baffle, motor control for quick switching of paper core thickness specifications, easy adjustment. The operation of the baffle is simple and convenient for daily cleaning and maintenance.

6. Convenient tool holder adjustment method, easy operation, and reliable structure.

7. Independent control cabinet, equipped with a 10 inch large touch screen, with complete command functions to meet daily production needs.Basic parameters of equipment model

Project Parameter Equipment model HX2000-600G Core paper (width x roll diameter) 2000mm×Φ1400mm Maximum width of core paper 2000mm Maximum stretching width of finished paper core 1600mm Effective unwinding diameter Φ1200mm-Φ1400mm Inner diameter of tube core Φ76mm-Φ100mm Core paper weight 90g-140g Adhesive Starch adhesive Finished paper core thickness 8-80mm Cross cutting production speed of honeycomb paper core 600 times/min (thickness 8mm, paper core weight 90-140 grams) Honeycomb flatness ±0.1mm Heating method electromagnetic heating Rated voltage Three phase AC 380V and 220V AC Rated frequency 50HZ Equipment installed power About 60KW (heating power 20KW) Normal production electricity consumption 60KW*40%-60% Total weight of equipment About 30T Equipment external dimensions 24500mm in length, 4500mm in width, and 3000mm in height Component Name Power Notes Cross cutting machine 4.5KW Servo feeding motor Cross cutting machine 3.0KW Feed motor Cross cutting machine 7.5KW Cutting blade drive motor Composite coating adhesive 3.0KW Glue machine drive motor Composite coating adhesive 1.0KW Adhesive machine transverse motor Electromagnetic heating plate 20.0KW Composite heating Laminator 4.0KW Belt driven motor Paper core coated with adhesive 4.0KW Glue machine drive motor 1 set Shaftless bracket 4.0KW 1 set of hydraulic press drive motor

Semiauto corrugated cardboard carton box flexo printing slotting die-cutting machinery

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.