Partition assemble machine

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

Application and characteristics

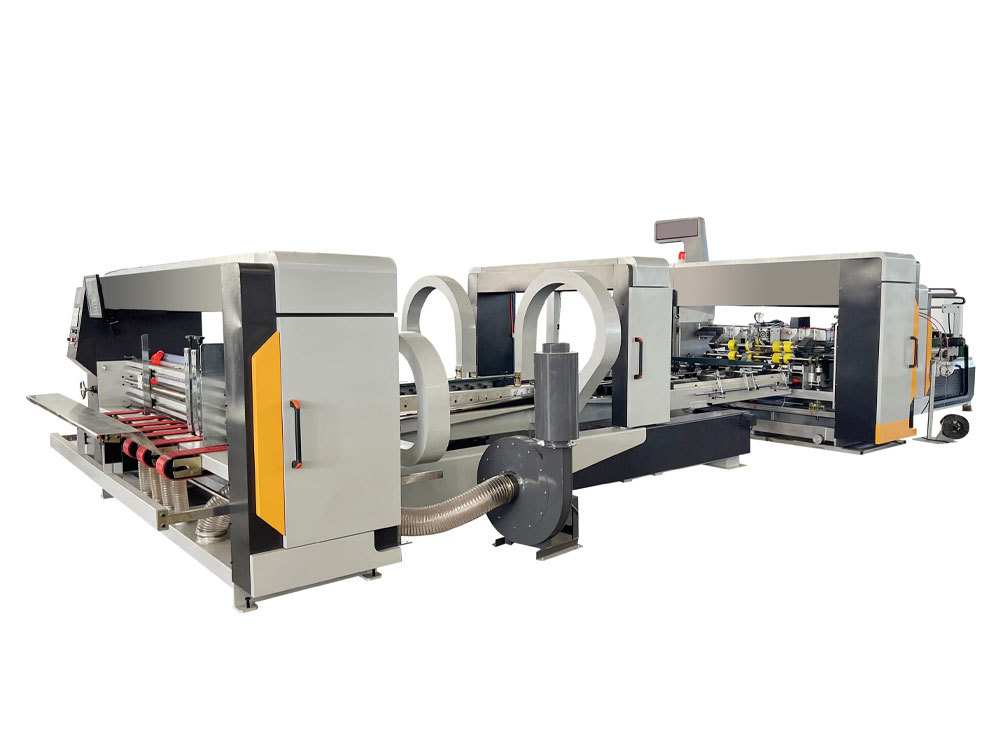

DH900X500 6N serious automatic partition assembler machine is optimized to be a new partition assembler devices on the basis of absorbing the advantage of equipment at home and abroad in our factory. The equipment takes the place of the traditional manual operation made, automatic complete insertion of clapboard, saving labor costs, effectively improve the production efficiency at the same time. It is the ideal packing equipment of fruit and vegetable, glass ceramic, plastic and so on.

Structure features

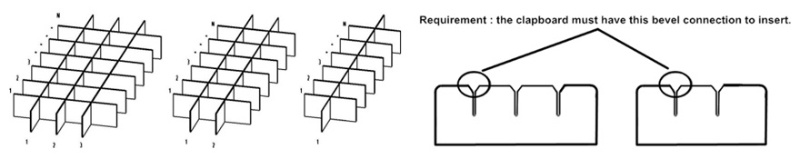

1.Suitable for the auto insertion of all kinds of carton clapboard.

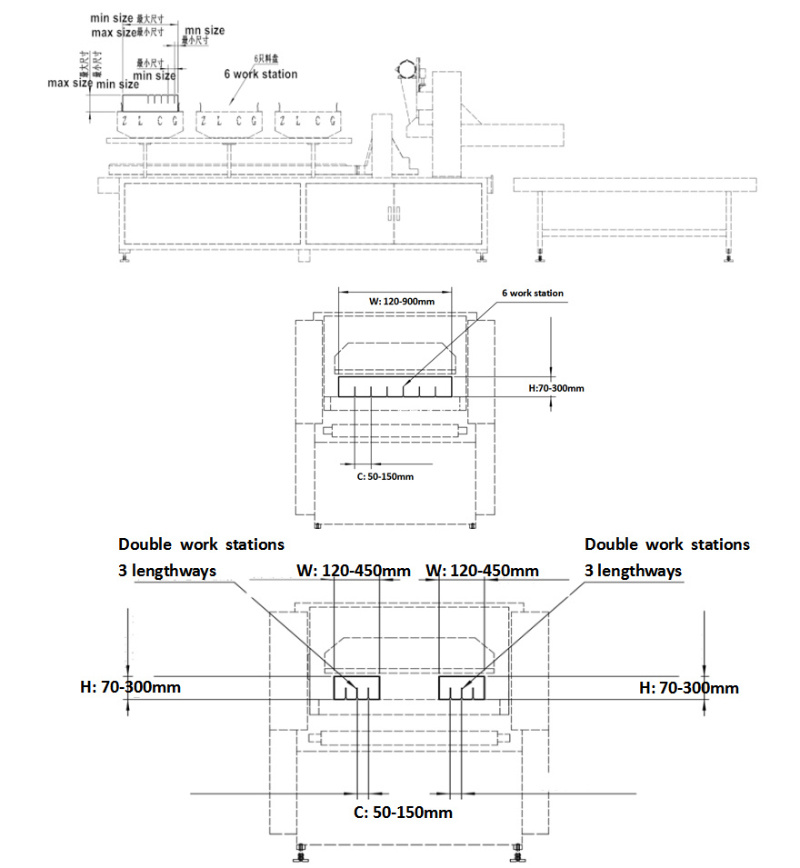

2.Vertical direct using vacuum adsorption feeding, landscape orientation using servo feeding , quick and accurate.

3.Longitudinal and transverse to cross the two pieces of paper at the same time.

4.Longitudinal feeding shaft adopts electric lifting.

5.Landscape orientation feeding worktable lifting adopts electric adjustment.

6.Electric adjust the clapboard height in landscape orientation.

7.Output in double work positions, high efficiency and energy saving.

8.Touch screen input control, electric to adjust the clapboard parameters.

9.Comprehensive using of pneumatic and electric control, to ensure the advancement of machine control.

10.Using compressed air storage tanks for gas centralized supply, gas supply pressure stability, enough gas source.The gas devices get the gas from the primary tracheal , independent control, no influence between each other.

11.Equipped with fault detection device, auto stop the machine when paper blocking.

Advantages introduction

1.Instead of traditional manual operation mode, reduce the manpower cost, high efficiency and energy saving.

2.Touching screen configuration, easy operation.

3.All parts is made of high quality raw materials, after precision machining equipment, long service life.

4.Science advanced mechanical structure, adjust easily in short time, easy to use and maintenance.

5.Purchased components selects the high quality brand products at home and abroad, the quality is guaranteed.

Machine model introduction

Technological parameter

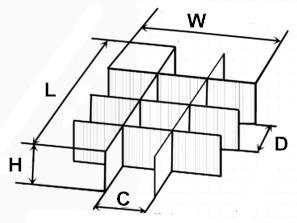

Power 10kw Not include air compressor Host belt speed 15-30m/min Clapboard combining form 3*(1~n) In double working station Longitudinal clapboard feeding track No. 6 Horizontal clapboard feeding track No. 1~12 Clapboard size Length L=120~500mm Clapboard thickness 1.5~7mm Height H=70~300mm Width W=120~450mm(double station) Width W=120~900(single station) Lattice space C=50~150mm Lattice space D=30~150mm Working speed 30-60groups/min Working speed is connected with clapboard size and clapboard combining form Machine weight 3000kg Overall dimension 5500x2200x2000mm Note: when width of clapboard is greater than 450mm, the machine just can work in single station.

Air compressor or air compressor station requirement: 6kgf/cm².

Power supply Can be customized Total power 8.0 - 9.0 kw Design speed 60 sets/min (double station speed) Economical speed 40 sets/min (double station speed) Air source pressure 0.6 - 1.0 MPa

Partition assemble machine

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.