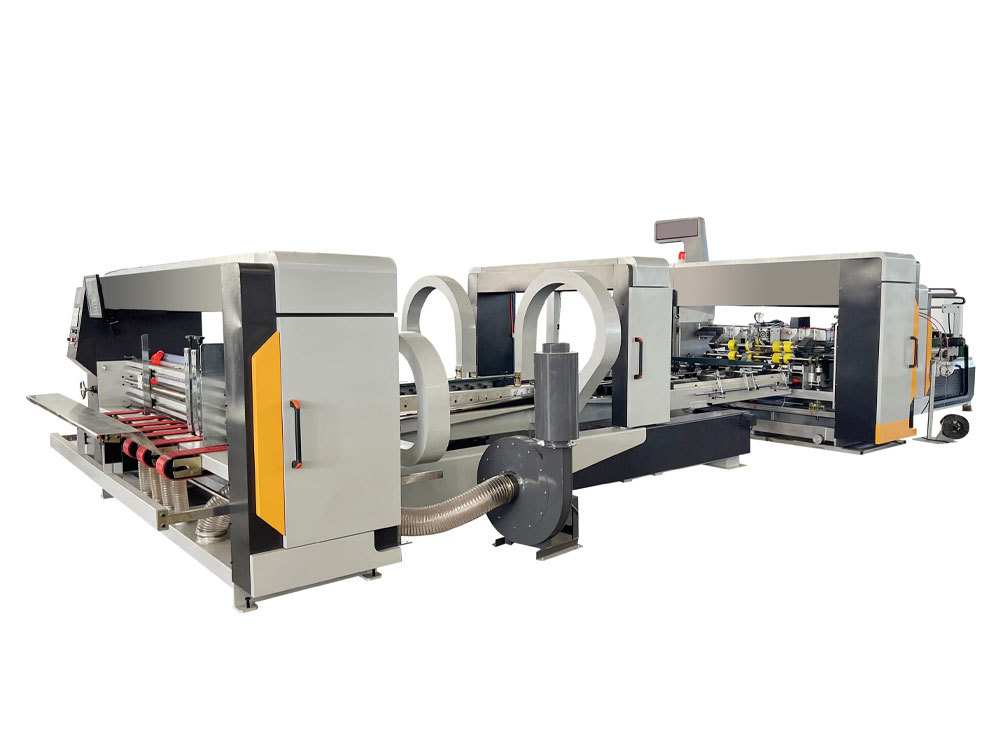

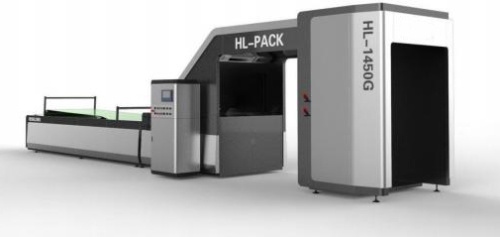

HL-1450G /1700G Full servo computer laminator machine

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

The biggest bright point of our company full automatic high speed laminator

First,computerization, all the operating data are reflected in the microcomputer ,that not only improve the work efficiency, reduce the work strength of employees, and strengthen the quality control of the processed products.

Second, the fast speed, computerized high –speed mount, up to 15000sheets per hour (within 700MM of paper).

Third, glue coating device: high precision coating conveyor with paper and rubber wheel edge rubber mechanism automatic liquid surface control, high-speed operation without overflow glue, can adjust glue reflux.

Fourth, sensing compensation alignment device: using multiple sets of electric eyes sensing surface paper and bottom paper forward relative position, so that the servo motors on both sides of the surface paper independent drive, compensation for the upper and lower paper alignment, adhesion accuracy ± 1.0, accurate and smooth.

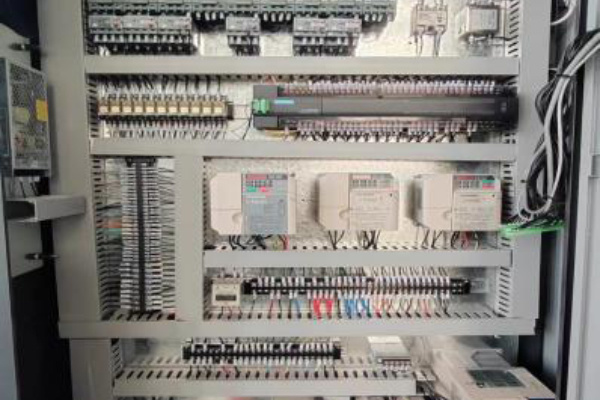

Fifth, full functions electronic control system: the application of human-computer interface and PLC program light display, can automatically detect operating conditions, abnormal display and work records. Electrical protection is more completely, electrical features "CE" standards .

Automatic high speed paper-making process as the basis of the products, my company is more strict, more professional. As the main power of the machine, our company adopts the "Siemens" motor as the main motor, and its running parameters are all high-end products in the industry;

The key parts of the bearings use "SKF" to account for more than 90 % of the entire machine: the entire machine electrical device adopts PLC program control: frequency conversion speed adjustment, and the photoelectric use of "Omron"; The button uses "Schneider" and so on. The bottom paper adopts servo control, and the wide edge transmits the belt transmission, which effectively ensures the accurate delivery and accurate alignment of the bottom paper. As a running transmission mode, our company adopts synchronous belt drive, synchronous belt with the well-known brand "Gates" as the first choice, small noise, accurate transmission, and smooth operation. Glue coating device(coating roller) adopts high precision mirror roller, which provides more powerful guarantee for the control of glue coating and avoiding the waste of glue. The transmission paper part uses a PU circular band and a lower fan combination to ensure that the paper is running. Both sides of the servo Feeder for the corresponding position compensation. As a high-speed paperboard "Feeder" plays a key role, as the company's supplier "Fanyuruida" professional standards are obvious to all. The main wall plate is processed by the processing center, thus effectively avoiding the machine coordination error caused by the processing.The protectivecoverisprocessed for the digital control center, and the appearance is more beautiful and the structure is more reasonable. The external method is electrostatic spraying and the atmosphere is solemn.

Product parameters

Main technical parameter Machine model HL-1450G HL-1700G Max paper size 1450*1450mm 1700*1450mm Min paper size 400*380mm 400*380mm Surface paper thickness 200-800g/m² 200-800g/m² Bottom paper thickness 0.5-12mm 0.5-12mm Machine speed 176m/min 176m/min Laminating precision ±1mm/m ±1mm/m Machine size 14000*2500*2400mm

(L * W * H)14000*2700*2400mm

(L * W * H)Machine power 25KW 28KW Machine weight 7.2T 7.8T Feed paper unit

Adopt unique design giving paper head of Japan, strong inhalation, supply paper smooth, smooth and accurate. According to the needs of the products, the speed of push paper can be arbitrarily adjusted, the accumulation and transmission of paper can be leveled and stabilized, and the height of paper accumulation can be controlled by photoelectricity. Stable and smooth conveyance of pilepaper.

Bottom feed paper unit

1.Punched belt suction paper feeding mechanism:

Imported punch belt suction paper delivery mechanism, strong suction,smooth transmission of paper. Suitable for paper 300g/m above card and A, B, C, E, F, N, as well as three, five, seven layers of cardboard, high-speed transmission paper smooth and accurate.2. Leading edge feeding is mechanism:

Leading edge feeding is mechanism better for 3,5 and 7 layers corrugated cardboard.

Control unit

The entire machine electrical adopts PLC program control,,Yasukawa frequency conversion speed adjustment, and various electrical components

detection switches are used in Japan, Germany, Taiwan and other companies' brand products. The operation control is accurate, the performance is stable, and the safety is strong.Glue supply ,coating glue system

1.Coating device, adopts the use of high precision mirror roller and rubber wheel automatic liquid surface control, high-speed operation, no overflow glue, can adjust glue reflux.Suitable for local mounting process.

2.The coating device is equipped with rubber shaft mesh, which is suitable for the lamination process of paperboard.

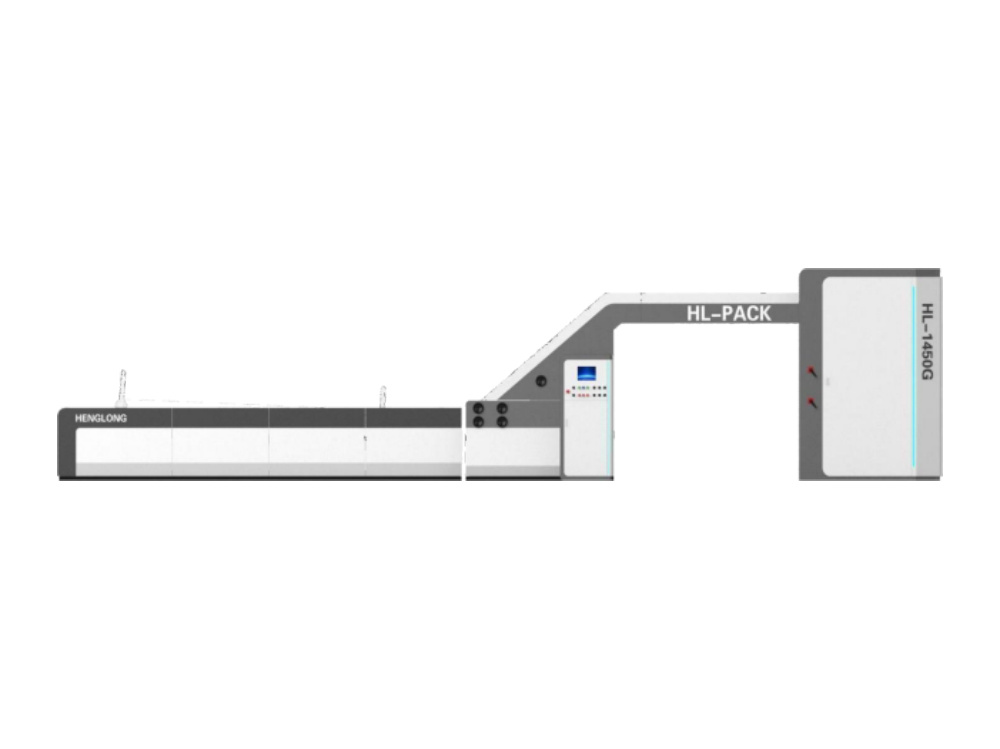

Foundation plans

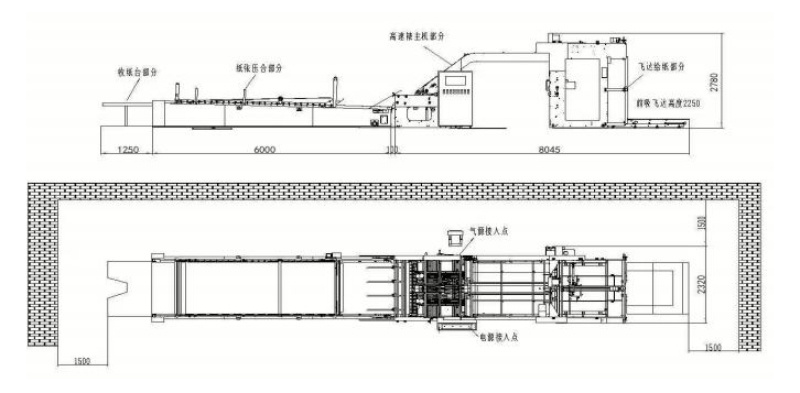

Foundation drawing of high-speed laminating machine HL-1450G

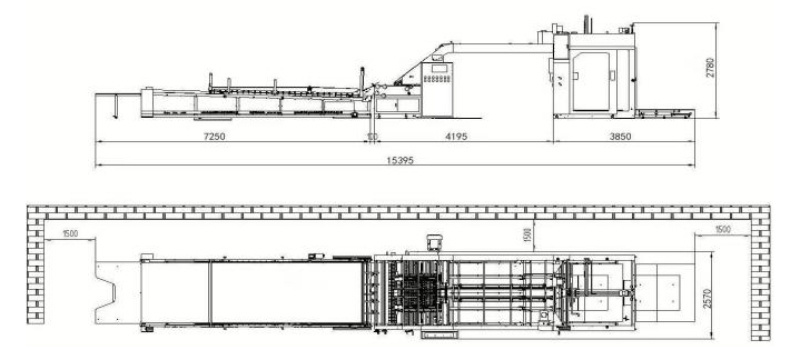

Foundation drawing of high-speed laminating machine HL-1700G

HL-1450G /1700G Full servo computer laminator machine

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.