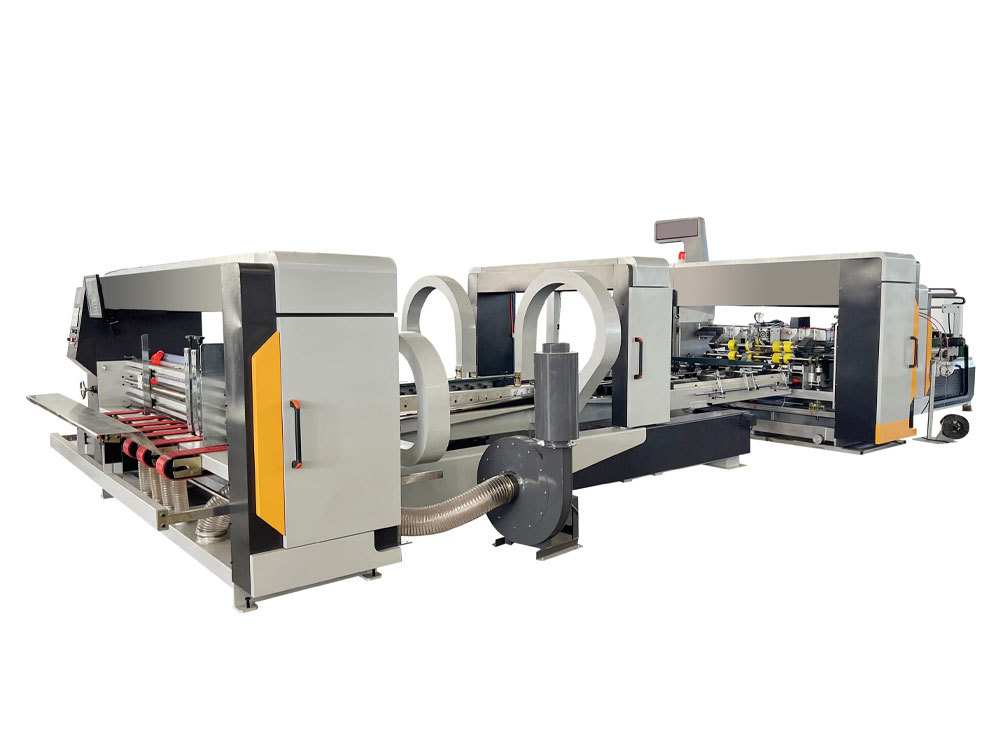

WJ-150-1800 five ply corrugated cardboard production line

We can provide a complete production line and individual parts to complete customers' own line.

If you need customized carton machinery, Contact US !

Products Category

Tag list

- 产品描述

-

WJ150-1800-Ⅱtype five layer corrugated paperboard production line Specification Equipment name QTY Remark

Hydraulic shaftless mill roll stand 5set Spindle 240mm, hyperbolic heavy rocker, toothed chuck , multi-point brake, hydraulic drive lifting, panning left and right on the middle.

The guide track is 6000mm and the trolley is welded with 10mm.Rail and Tracks 10set

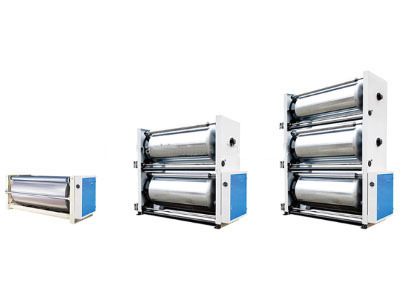

Top paper preheat cylinder 2set Roller 900mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°.

Core paper preheat cylinder 2set Roller 900mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°.

Mould single facer 2set Corrugated main roller 320mm,material with 48CrMo alloy steel, tungsten carbide.Tile roll modular group lifting transfer.Airbag ballasting structure,import main bearing,PLC automatic control glue,HMI touch screen. Breaks automatic parking relief,steam heating way.

Triple preheater 1set Roller 900mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°. The angle of wrap is automatically adjusted according to the speed of the vehicle, the angle of the wrap angle is displayed on the touch screen, and the parking automatically returns to zero to facilitate paper penetration.

Double glue machine 1set The diameter of the roller is 268mm.

Independent variable frequency motor drive, manual. Adjustment of glue clearance.Conveyor bridge 1set 180mm main beam channels, independent inverter motor drive pull paper feed, adsorption tension.Electric correction.

Double facer 1set The frame is 400 mm national standard channel steel, chrome plated hot plate 600 mm *16pieces, the entrance uses arc-shaped hot plate to make the facial paper heat up extremely quickly, and the design structure of the whole pressure plate is touched.

NC thin blade slitter scorer 1set Tungsten alloy steel, seven knives twelve lines,zero-pressure line type. Schneider servo computer automatically discharge knife, suction outlet width automatically adjusted.Closed electric control box, plus air conditioning and dehumidification.

NC cutter helical knives 1set Full AC servo control, energy storage brake, helical blade structure, oil-immersed gears,10.4-inch touch screen display.Closed electric control box, plus air conditioning and dehumidification.

Automatic large gantry stacker 1 set Servo drive platform lift, four sections of frequency transmission, automatic points in batches, automatic stacking discharge, imported high-strength belt output,out paper side standard transport aircraft. Automatic double stacker 1set auto counter and auto output stacked boards.

Pneumatic baffle in the paper feeding section of the flat belt, frequency conversion control multi-stage speed, the stacking is stable and neat, and does not damage the cardboardGlue station system 1set Customers -owned pipeline.Glue configuration is composed by carrier tank,main tank,storage tank,and send plastic pump,back plastic pump. Gas source system 1set Gas source is prepared by the customers. Steam system 1set Steam system components used in all GB valves.Including rotary joint,upper and lower dispenser.traps,pressure table and so on.Customer-owned boilers and pipes. Electrical control cabinet system Electronic control system::fingerless single facer,driving part,NC thin blade slitter scorer,double facer,glue machine all adopt frequency motor,delta frequency control system.operation interface easy and convenient,Speed display control cabinet with each unit speed display, the unit call, emergency stop function.The main contactor by French Schneider (Schneider) famous brand products, the main motor adopts SIEMENS, main bearing by Japan NSK, main inverter, PLC by SIEMENS.

WJ-150-1800 five ply corrugated cardboard production line

We can provide a complete production line and individual parts to complete customers' own line.

If you need customized carton machinery, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.