Understanding the Cassette Type Single Facer Machine: A Key Player in Packaging Solutions

Jun 21,2025

The Cassette Type Single Facer Machine is a specialized piece of equipment widely used in the packaging industry, particularly for the production of corrugated board. This machine plays a crucial role in the manufacturing process by producing single-faced corrugated sheets, which are vital for various packaging applications. Understanding the workings and advantages of this machine can significant

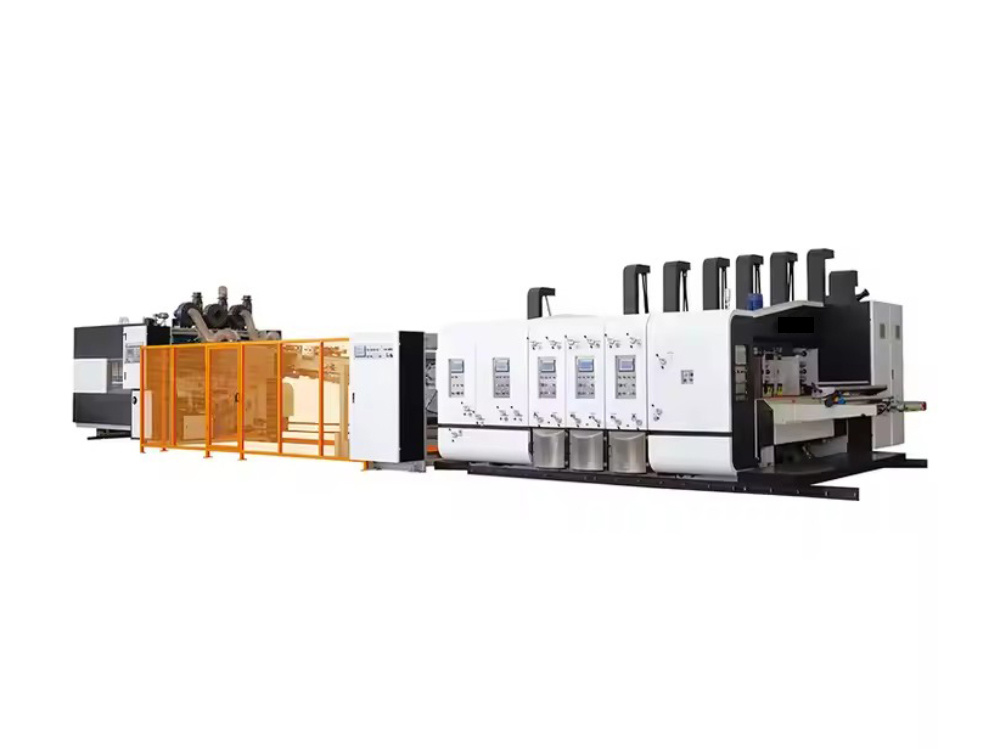

The Cassette Type Single Facer Machine is a specialized piece of equipment widely used in the packaging industry, particularly for the production of corrugated board. This machine plays a crucial role in the manufacturing process by producing single-faced corrugated sheets, which are vital for various packaging applications. Understanding the workings and advantages of this machine can significantly benefit manufacturers looking to enhance their production efficiency and product quality.

At its core, the Cassette Type Single Facer Machine operates by combining a liner and a medium (the fluted paper) to create a single-faced corrugated sheet. This process involves heating and bonding the materials together, typically using a combination of pressure and adhesive. The term "cassette" refers to the modular design of the machine, allowing for easy replacement of parts and quick adjustments, which can lead to improved operational efficiency.

One of the significant advantages of the Cassette Type Single Facer Machine is its ability to produce high-quality corrugated material with consistent flute height and spacing. This precision is vital for ensuring that the final product meets the required specifications for strength and durability, which are critical factors in packaging. Additionally, the modular design often allows for easy maintenance, reducing downtime and ensuring a more streamlined production process.

Moreover, the Cassette Type Single Facer Machine can typically handle various paper grades and sizes, providing manufacturers with the flexibility to adapt to different production needs. This versatility makes it an ideal choice for businesses looking to diversify their product offerings without investing in multiple machines.

Efficiency is another area where the Cassette Type Single Facer Machine excels. Its design often includes features that optimize the speed of production while maintaining quality control. With the ability to produce large volumes of single-faced sheets in a short time frame, manufacturers can meet high demand without compromising on quality.

In summary, the Cassette Type Single Facer Machine is an invaluable asset in the packaging machinery sector. Its ability to produce high-quality corrugated sheets with efficiency and versatility makes it a preferred choice for many manufacturers. As the packaging industry continues to evolve, the importance of such advanced machinery cannot be overstated, especially for businesses aiming to remain competitive in a fast-paced market. Investing in a Cassette Type Single Facer Machine could be a pivotal step for manufacturers looking to improve their production processes and product offerings.

At its core, the Cassette Type Single Facer Machine operates by combining a liner and a medium (the fluted paper) to create a single-faced corrugated sheet. This process involves heating and bonding the materials together, typically using a combination of pressure and adhesive. The term "cassette" refers to the modular design of the machine, allowing for easy replacement of parts and quick adjustments, which can lead to improved operational efficiency.

One of the significant advantages of the Cassette Type Single Facer Machine is its ability to produce high-quality corrugated material with consistent flute height and spacing. This precision is vital for ensuring that the final product meets the required specifications for strength and durability, which are critical factors in packaging. Additionally, the modular design often allows for easy maintenance, reducing downtime and ensuring a more streamlined production process.

Moreover, the Cassette Type Single Facer Machine can typically handle various paper grades and sizes, providing manufacturers with the flexibility to adapt to different production needs. This versatility makes it an ideal choice for businesses looking to diversify their product offerings without investing in multiple machines.

Efficiency is another area where the Cassette Type Single Facer Machine excels. Its design often includes features that optimize the speed of production while maintaining quality control. With the ability to produce large volumes of single-faced sheets in a short time frame, manufacturers can meet high demand without compromising on quality.

In summary, the Cassette Type Single Facer Machine is an invaluable asset in the packaging machinery sector. Its ability to produce high-quality corrugated sheets with efficiency and versatility makes it a preferred choice for many manufacturers. As the packaging industry continues to evolve, the importance of such advanced machinery cannot be overstated, especially for businesses aiming to remain competitive in a fast-paced market. Investing in a Cassette Type Single Facer Machine could be a pivotal step for manufacturers looking to improve their production processes and product offerings.

TAG:

PREVIOUS:

Contact Us

Phone/WhatsApp

Address

QuZhuang Village, DongGuang County, CangZhou City, HeBei Province, China